How to use RAFT agents

RAFT polymerization is a method of living radical polymerization that can be used to synthesize "polymers with a uniform molecular weight distribution". We would like to introduce a simple protocol for RAFT polymerization in response to the customers' comments such as "I am interested in RAFT polymerization, but I don't know how to use RAFT agents" or "Although this is a bio-research laboratory, I am interested in precision polymerization polymers and want to try synthesizing them."

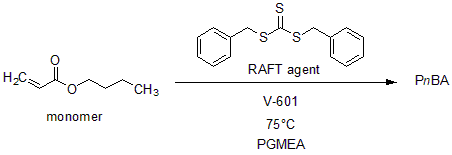

Fig.1 Example of synthesis of poly n-butyl acrylate

Protocol

- Add V-601 (100 mg) and PGMEA (9.90 g) to a 10 mL vial and prepare 1 wt% PGMEA solution.

- Add a RAFT agent (S,S-dibenzyl trithiocarbonate) (0.158 g, 0.544 mmol) and nBA (8.00 g, 62 mmol) to a 50 mL eggplant flask, and add the initiator solution prepared in [1] (3.13 g, 0.136 mmol as V-601) to dissolve the mixture in PGMEA (5.1 g).

- When [2] has completely dissolved, attach a reflux tube and conduct bubbling with nitrogen gas for 30 minutes at room temperature.

- Let it react for 2 hours in a water bath at 75°C under a nitrogen atmosphere.

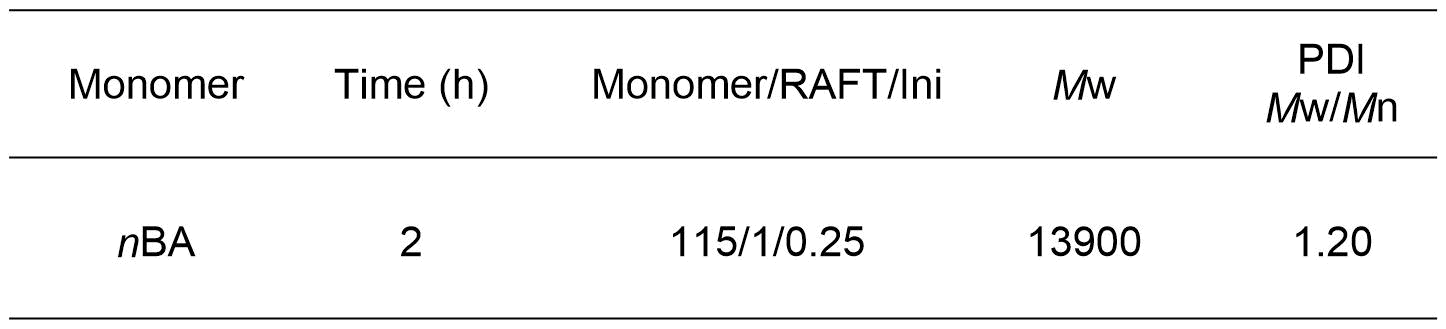

- By analyzing the formed polymer with GPC, poly(n-butyl acrylate) with Mw = 13,900 and Mw/Mn = 1.20 is obtained.

Fig.2 Result

*The experimental protocol and the result introduced here are the actual measurement data by FUJIFILM Wako.

What is RAFT polymerization?

One of the controlled living radical polymerization methods is polymerization that uses reversible addition-fragmentation chain transfer agents, which are sulfur compounds. This polymerization is generally called RAFT polymerization, and it is an effective method for synthesizing polymers with a narrow molecular weight distribution. Since physical properties such as mechanical, thermal, and optical properties can be controlled by controlling the molecular weight distribution of the polymer, RAFT polymerization has come under the spotlight as a polymerization method with expectations for use in high-function polymer materials.

In RAFT polymerization, thiocarbonylthio compounds are used as the chain transfer agents (hereinafter referred to as RAFT agents). The basic structure of a RAFT agent is one that includes a thiocarbonylthio group (S=C-S), where radical addition and fragmentation is relatively easy (Figure 1). There are dithiobenzoate types, trithiocarbonate types, dithiocarbamate types, and dithiocarbonate types as classified by the type Z, and these have different characteristics from one another.

In general, dithiobenzoate-type RAFT agents and trithiocarbonate-type agents are selected for polymerization of conjugated monomers, and dithiobenzoate-type agents are selected for polymerization of non-conjugated monomers. It is important in RAFT polymerization to select a RAFT agent that is most suited to the reactivity of the monomer.