Importance of compatibility in RAFT polymerization

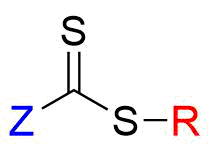

RAFT polymerization is a reversible addition-fragmentation chain transfer living radical polymerization method, and it is effective in the synthesis of polymers with a narrow molecular weight distribution. A thiocarbonylthio group (S=C-S) with R and Z as substituent groups is used for RAFT polymerization as a chain transfer agent (hereinafter referred to as a RAFT agent) .

Fig.1 Basic structure of RAFT agent

In order to conduct RAFT polymerization efficiently, it is necessary to select a suitable RAFT agent considering the reactivity of the monomer species to be used in polymerization. Literature on the combinations of monomer species and RAFT agents is introduced below as an example. The monomer species are classified by their structure into conjugated monomers and non-conjugated monomers (Table 1).

| Monomer classification | Typical monomer |

|---|---|

| Conjugated monomer | styrene (meta) acrylate (meta) acrylamide |

| Non-conjugated monomer | vinyl acetate N-vinylpyrrolidone |

Table 1 Monomer classification

A characteristic of RAFT polymerization is the wide application range of the monomer species, as it can be used to control the polymerization of not only conjugated monomers, but also non-conjugated monomers.

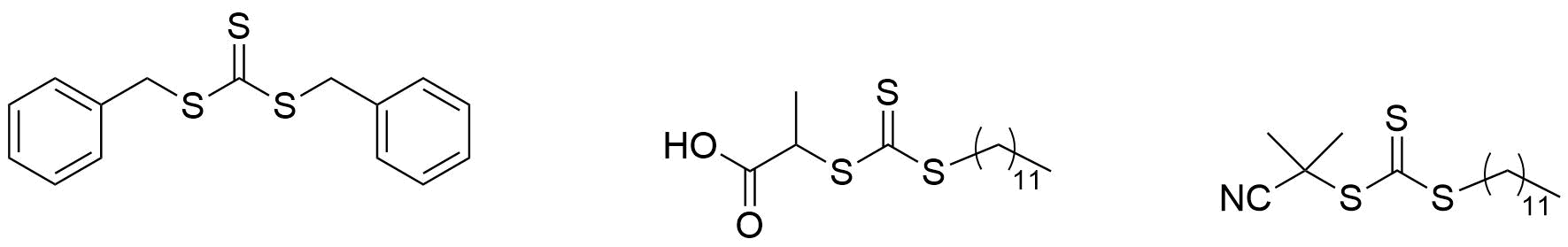

Among these, RAFT agents shown in Figure 2 are considered useful with conjugated monomers (styrene [St], n-butyl acrylate [nBA], and methyl methacrylate [MMA]). Table 2 shows some specific examples of RAFT polymerization.

Fig.2 Types of RAFT agents

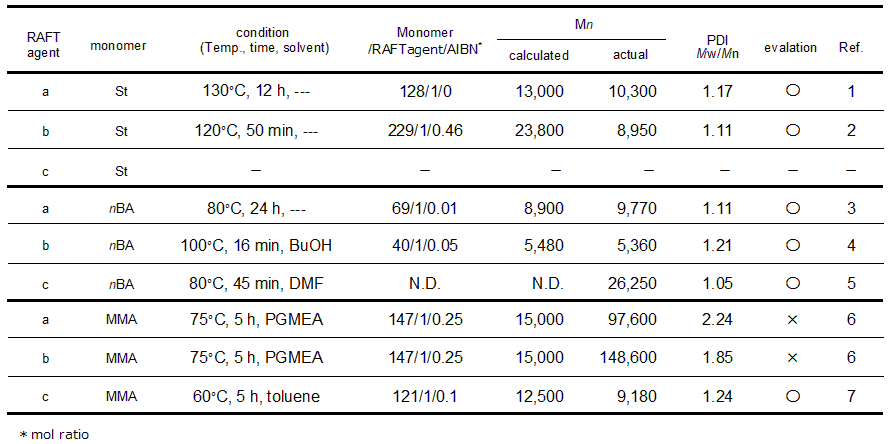

Table 2 Polymerization examples of 3 types of monomers and RAFT agent

Table 2 Polymerization examples of 3 types of monomers and RAFT agent

Examples of polymerization with RAFT agents using three monomers

There are many high-temperature systems in the polymerization of St, and polymers with a narrow molecular weight distribution can be obtained when RAFT agent (a) or (b) is used. For nBA, any RAFT agent can be used to produce polymers with a narrow molecular weight distribution. For MMA, RAFT agents (a) and (b) cannot be applied, and only RAFT agent (c), which has a tertiary carbon, has achieved favorable results.

These results should show that appropriate temperature conditions, and polymerization time as suited to the monomer species, are required, not to speak of selection of the RAFT agent.