Information on the Adoption of Containers Made of Biomass Plastic

Fujifilm Wako will change the containers of some of reagents to containers made of environmentally friendly biomass plastic.

In the Japanese market, this is the first attempt in the reagent industry, although containers made of biomass plastic has already been adopted by food and pharmaceutical manufacturers.

Background

Year after year, the demand of biomass plastic has been increasing due to growing environmental awareness.

In Japan, the introduction of plastic bag fee system, Tokyo Olympics, etc. have increased interest in global environmental issues, and the Japanese government has set a target of using approx. 2 million tons/year of biomass plastic by FY2030.

As a leading reagent company, Fujifilm Wako has decided to adopt environmentally friendly packaging materials.

What is Biomass Plastic?

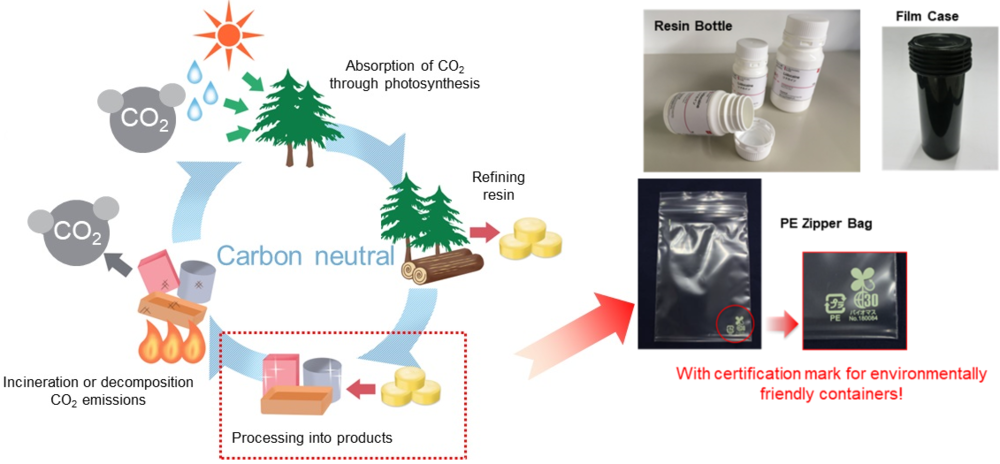

Biomass plastic is a plant-derived polyethylene that is chemically or biologically synthesized from renewable biomass resources. It has the feature of not increasing the concentration of CO2 in the atmosphere even when the container is incinerated, due to the carbon-neutral characteristics unique to biomass plastic (a renewable resource). This is expected to contribute to the prevention of global warming and reduction of dependence on petroleum resources.

Biomass Plastic Certification System in Japan

| Under the jurisdiction of Ministry of Economy, Trade and Industry of Japan |

JORA (Under the jurisdiction of the Ministry of Agriculture, Forestry and Fisheries of Japan) |

||

|---|---|---|---|

| -Characterized by decomposition by the action of microorganisms after use and at the time of disposal, ultimately changing into water and carbon dioxide gas. -Biodegradable plastics and natural organic materials content of 50 wt% or 50 vol% or more as listed on the Positive List in the product. |

|||

What are SDGs?

SDGs stand for Sustainable Development Goals, and the 2030 Agenda for Sustainable Development, adopted at the UN Summit in September 2015, consist of 17 goals to be achieved.

Biomass plastics contribute to the following seven items.

| Reduction of petroleum-derived plastic use |

By 2030, waste generation will be substantially reduced through prevention, reduction, recycling, and reuse of waste. |

CO2 Emissions Process Comparison

High purity plastics improve the recycling rate by converting waste into recycled resources*

*Improved recyclability of plastics

Reduce dependence on petroleum resources and improve resource recycling by switching from exhaustible resources (petroleum) to renewable resources (biomass)

Reduction of petroleum-derived CO2 emissions generated during incineration due to the carbon neutral properties of plant-derived polyethylene*

*CO2 emission reduction rate = approx. 70%.

I see! So, we can reduce the use of limited petroleum resources.

Reagent containers are difficult to recycle, but could reduce the environmental impact by buying reagents from Fujifilm Wako.

In Europe, environmental countermeasures are shifting from the use of "biodegradable plastics" to the use of "biomass plastics (non-biodegradable).

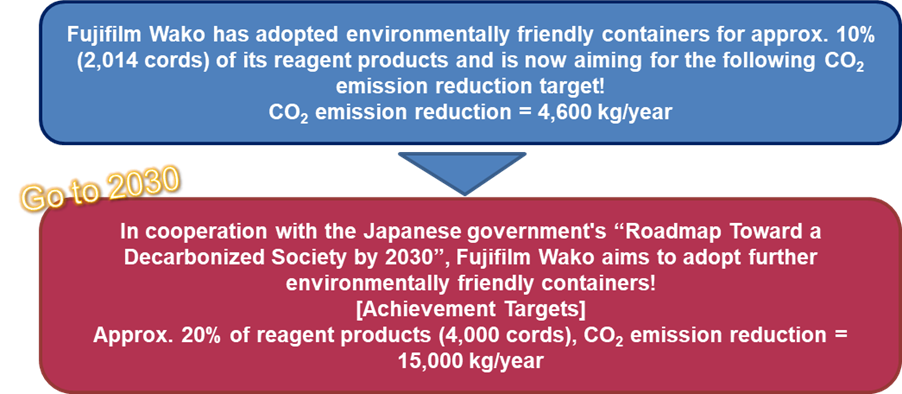

Fujifilm Wako's efforts are contributing to the Japanese government's Roadmap for Bioplastics Introduction.