[Technical Report] Rapid Analytical Method for Pesticides in Water Using Online SPE-FastGC/MS/MS System

This article was written by Mr. Tomonori Asai, AiSTI SCIENCE Co., Ltd., Technical & Marketing Group, for Vol. 18 (November 2021), of ChemGrowing.

The content of this article is from the time of publication. It is not the latest information due to new knowledge and changes in regulatory rules after original publication.

Introduction

When an accidental release of environmental contaminants to river water occurs, analytical results outlining the type and concentration of the contaminants are required immediately. Moreover, the development of more rapid analytical methods allows for more samples to be processed in a shorter period of time.

This report presents the results of the recovery test of pesticides in river water performed by the fully automatic and rapid "Online SPE-FastGC/MS/MS system." By combining a device "SPL-P100" that enables fully automatic online analysis from solid-phase extraction to GC/MS/MS measurement with a "20 m column" and "FastGC/MS/MS system" that enables rapid separation measurement.

Online SPE-FastGC/MS/MS system

Equipment Overview

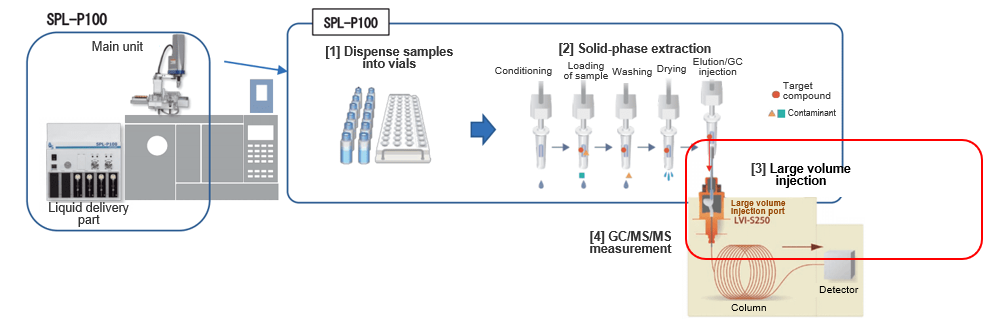

The outline of Online SPE-FastGC/MS/MS system is shown in Figure 1.

Figure 1. The outline of Online SPE-FastGC/MS/MS system

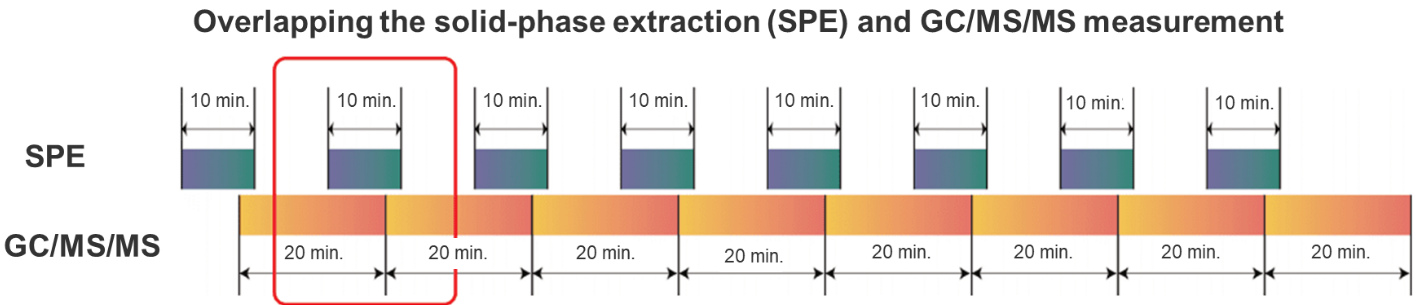

The Online SPE-FastGC/MS/MS is a system in which samples are loaded to solid-phase extraction using the online SPE-GC interface SPL-P100 developed by AiSTI SCIENCE Co., Ltd.. The eluate is injected into GC for measurement by GC/MS. The SPL-P100 consists of a main unit and a solvent delivery unit, and by simply setting a sample, it is possible to perform all processes from solid-phase extraction to injection of sample into GC and GC/MS measurement automatically. Moreover, this system can efficiently operate the processing cycle by overlapping the pretreatment (solid-phase extraction) and GC/MS/MS measurement (Figure 2).

Figure 2. Analysis cycle of Online SPE-FastGC/MS/MS system

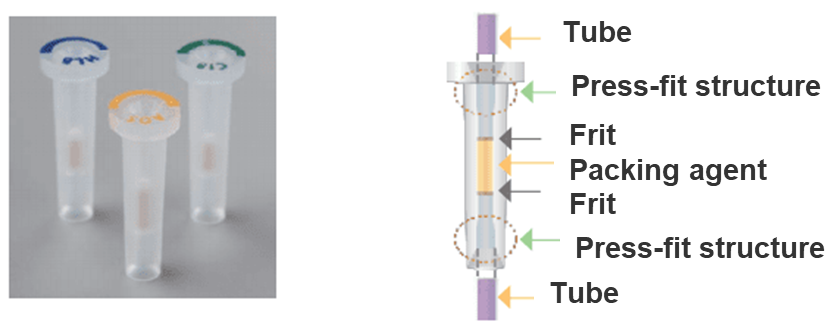

The online SPE-GC-dedicated solid-phase cartridge "Flash-SPE" and Large volume injector device for GC "LVI-S250" can be automated to work with this system.

Online SPE-GC-dedicated solid-phase cartridge "Flash-SPE" and its structure are shown in Figure 3. This solid-phase cartridge has a compact design with a very small filling amount of 2 to 5 mg, which enables the scale-down of the analytical system thereby reducing the sample load. The target compound can be eluted from the solid-phase with several tens of μL of solvent.

Figure 3. Flash-SPE solid-phase cartridge and its structure

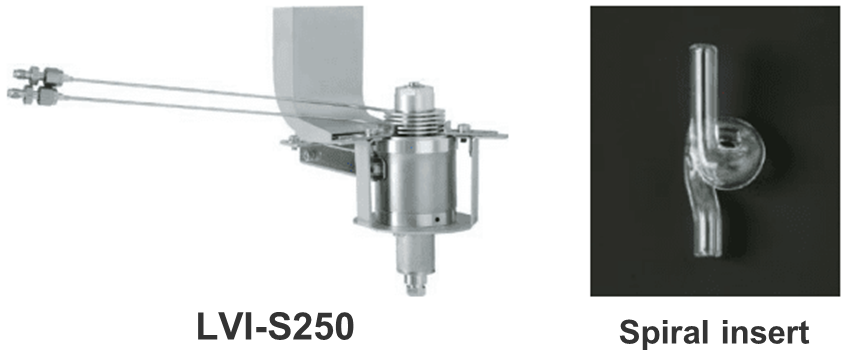

On the other hand, the Large volume injector device for GC "LVI-S250" uses spiral insert which is so-called "stomach shaped insert", and based on its shape, it is possible to inject up to 100 μL (Figure 4). By this method, the entire volume of several tens μL of the eluate eluted from the Flash-SPE can be injected into the GC.

Figure 4. Large volume injector device for GC "L VI-S250" and spiral insert

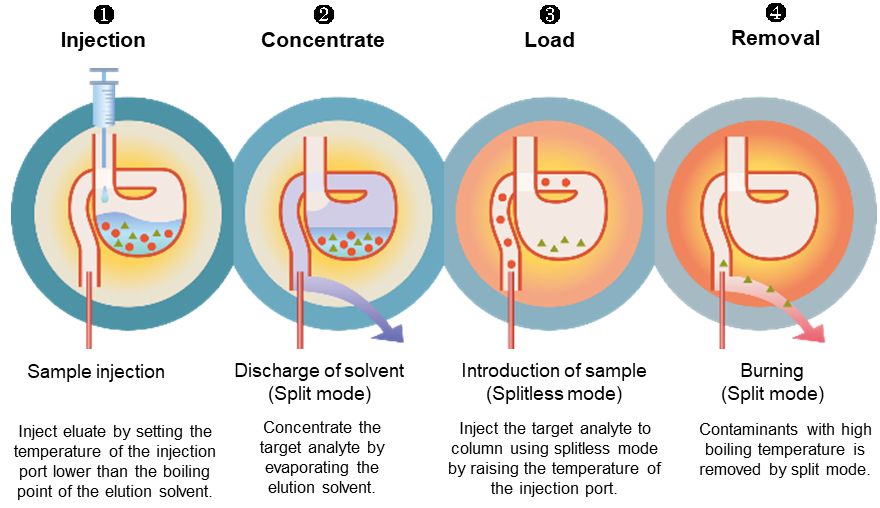

The outline of LVI-S250 is shown in Figure 5. Set the injection port temperature near the boiling point of the solvent at the time of sample injection, and discharge the solvent in a split mode after sample injection. Then raise the injection port temperature and introduce the target compound into the column in a splitless mode. Continue to warm, burn out the inside of the insert, and remove the non-volatile components in a split mode.

Figure 5. The outline of Large volume injector device for GC "LVI-S250"

In this example, GC/MS/MS capable of rapid ion intake "JMS-TQ4000GC (JEOL, Ltd.)" was connected to this system, and a short analysis column of 20 m was used for automation as Online SPE-FastGC/MS/MS system and further acceleration of analysis.

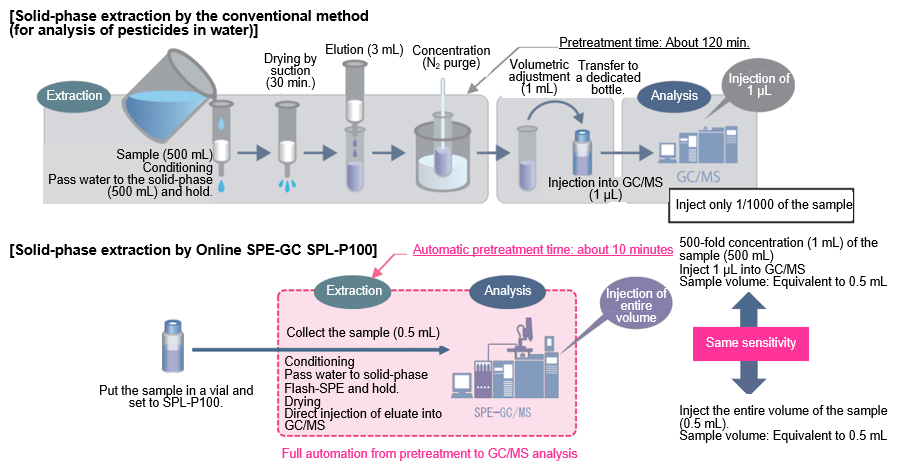

Comparison with Conventional Method

Comparison of the analysis of pesticides in water between Online SPE-FastGC/MS/MS system and the conventional method is shown in Figure 6. In the conventional method, load 500 mL of the sample on the solid-phase (500 mg) to hold the target compound, dry the solid-phase by suction and perform elution. After that, concentrate the solution to 1 mL, and inject 1 μL of the concentrate into GC. In this system, on the other hand, because Flash-SPE is used for solid-phase extraction, scale-down of sample collection is possible from 500 mL to 0.5 mL, and, as a result, the volume of eluate from the solid phase is as small as several tens of μL (40 μL in this report). Therefore, the entire volume can be injected into GC using LVI-S250.

Figure 6. Comparison of the analysis of pesticide in water between

Online SPE-FastGC/MS/MS system and the conventional method

That is, in the conventional method, concentrate 500 mL of the sample 500-fold to 1 mL, and inject 1 μL of it into GC. This is equivalent to 0.5 mL of sample. When this system is used, 0.5 mL of the sample is injected entirely, which is equivalent to 0.5 mL of the sample, and the absolute amount (sensitivity) of the sample to be introduced into GC is equivalent to that of the conventional method. Therefore, this system can obtain merits such as reduction of the amount of sampling, reduction of the amount of solvent used (cost reduction), shortening of pretreatment time, and automation while securing the sensitivity equivalent to that of the conventional method.

Analytical Method

Analytical Samples

River water

Mixture Standard Solution

The following mixture standard solutions manufactured by FUJIFILM Wako ware used.

- 66 Pesticides Mixture Standard Solution WQ-1-2 (Code No.168-26631, 164-26633)

- 15 Pesticides Mixture Standard Solution WQ-2 (Code No.169-23883, 163-23881)

- 48 Pesticides Mixture Standard Solution WQ-5 (Code No.161-26001, 167-26003)

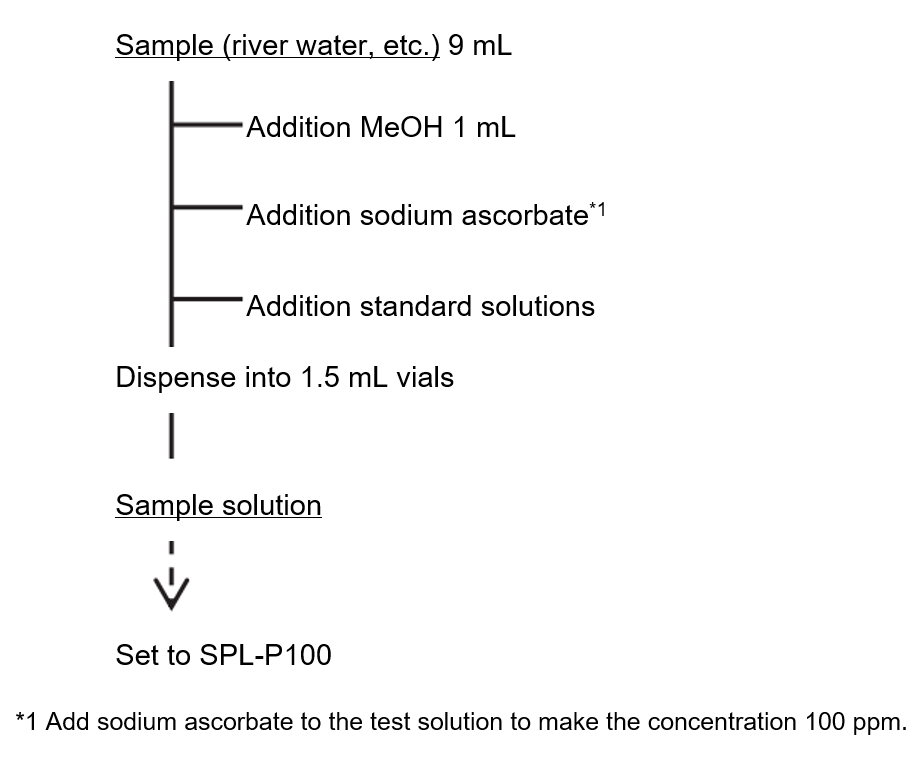

Sample Preparation

The flow of sample preparation is shown in Figure 7. To the sample, MeOH was added to make the volume ratio 10%, and sodium ascorbate was added to make the concentration in the sample solution 100 ppm. MeOH is used to suppress adsorption of the low-polarity compound to glass vials, sodium ascorbate is used to prevent oxidation of the target compound. The standard solution was subsequently added in the recovery test. The prepared sample was dispensed in a 1.5 mL glass vial and set to SPL-P100.

Figure 7. Flow of sample preparation

The analytical standard for calibration curve was prepared in the same manner using purified water.

Solid-phase Extraction

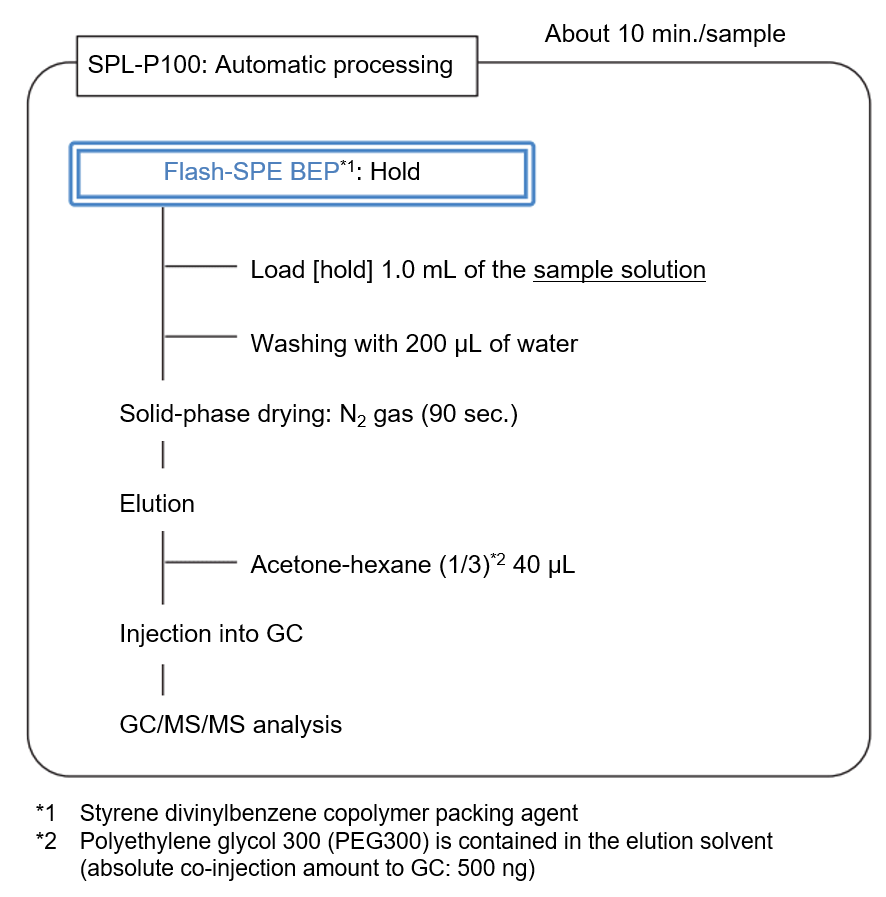

The flow of solid-phase extraction in SPL-P100 is shown in Figure 8. Solid-phase extraction was performed in Flash-SPE BEP, a styrene divinylbenzene copolymer (hydrophobic polymer), at SPL-P100.

Figure 8. Flow of solid-phase extraction (SPL-P100)

1.0 mL of the sample solution was loaded on BEP to hold the target compounds. Then, the BEP was washed with 200 μL of water to remove highly polar contaminants. Subsequently, BEP was dried by blowing nitrogen gas. It was eluted with 40 μL of acetone-hexane (1/3), and the entire volume was injected into GC. The acetone-hexane eluate (1/3) was prepared to contain polyethylene glycol 300 to make the absolute injection volume into GC 500 ng. This is to inhibit adsorption of the target compound to the active point (adsorption point) existing in the GC insert, column, ion source, etc.

Measurement Conditions

The total volume of the eluate from the solid-phase was injected into GC and measured by GC/MS/MS. In this system, a high speed separation measurement was performed using a 20 m column. The measurement conditions are shown in Table 1, and the measuring equipment is shown in Figure 9.

Table 1. Measurement conditions

| Measuring equipment | |

|---|---|

| Online SPE-GC interface | SPL-P100 (AiSTI SCIENCE Co., Ltd.) |

| Large volume injector device | LVI-S250 (AiSTI SCIENCE Co., Ltd.) |

| GC-MS | JMS-TQ4000GC (JEOL Ltd.) |

| GC conditions | |

| Column | VF-5ms, 0.25 mm i.d. x 20 m, df; 0.25 μm |

| Injection port heating program | 70℃ (0.35 min.) - 120℃/min. - 240℃ - 50℃/min. - 290℃ (13 min.) [Total 15.7 min.] |

| Solvent vent program | 55 kPa, 150 mL/min. (0.35 min.) - splitless - 50 mL/min. (3 min.) |

| Oven heating program | 60℃ (3 min.) - 25℃/min. - 270℃ - 10℃/min. - 310℃ (3 min.) [Total 18.4 min.] |

| Carrier gas | Helium |

| Column flow rate | 1.2 mL/min. |

| MS conditions | |

| IF temperature | 300℃ |

| Ion source temperature | 280℃ |

| MS measurement mode | SRM (Fast scan) |

Figure 9. SPL-P100+LVI-S250 (AiSTI SCIENCE Co., Ltd.), GCMS JMS-TQ4000GC (JEOL, Ltd.)

Product images are posted with permission from JEOL, Ltd.

Results

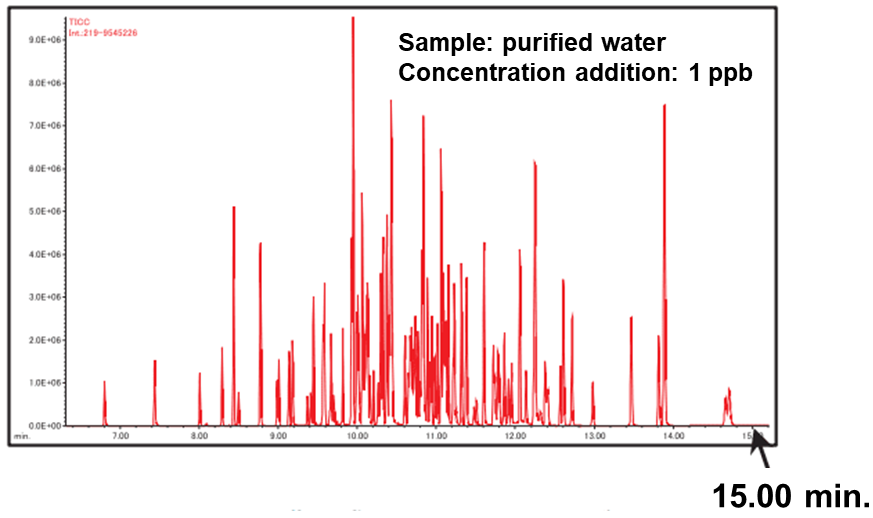

By using a 20 m column, the peak of the target pesticide was detected within 15 minutes, and 1 analysis including the burning out time could be performed in 18.4 minutes (Figure 10).

Figure 10. SRM chromatogram of pesticide

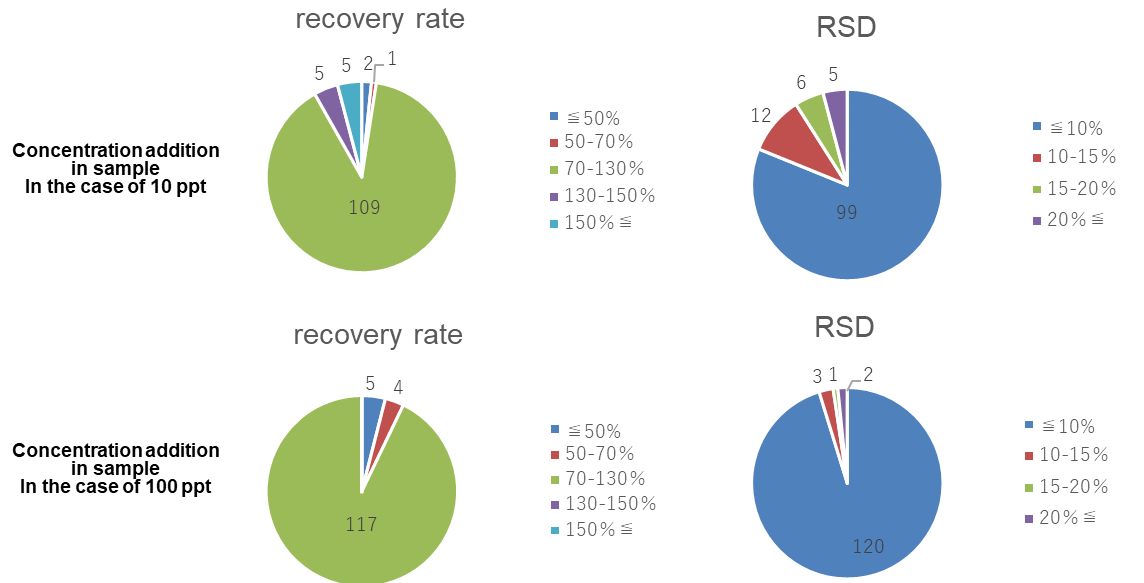

The distribution of recovery rate and RSD in recovery test performed with n = 7 is shown in Figure 11. The recovery rate was calculated by comparing the area obtained from the solid-phase extraction by adding the standard solution to purified water with the area obtained from the solid-phase extraction by adding the standard solution to river water.

Figure 11. Distribution of recovery rate and RSD

At a sample concentration of 10 ppt, 109 of 122 pesticides evaluated gave the recovery rate of 70 to 130%, and 99 pesticides showed the RSD of less than 20%.

At a sample concentration of 100 ppt, 117 of 126 pesticides evaluated gave the recovery rate of 70 to 130%, and 120 pestis showed the RSD of less than 20%.

Good recovery rate and reproducibility were obtained using this system.

Conclusion

The combination of online SPE-GC SPL-P100 and FastGC/MS/MS enabled more simple, rapid and precise analysis of pesticides in water. Since this system can process multiple samples efficiently in a short period of time, its usefulness was suggested also for monitoring in rivers and emergency cases such as spillage accident of contaminants.

Reference

Asai, T. et al.: Proceedings of the 29th Symposium of Environmental Chemistry (2021).