SPE Colum for Pesticides Analysis

Solid phase extraction (SPE) column for pesticide analysis, "Presep® Agri series", is a cartridge packed with styrene divinylbenzene-methacrylate to clean up residual pesticides easily. Two types available depending on clean-up methods (pressure method or vacuum method): Presep®-C Agri (Short) cartridge with both ends closed and Presep® Agri syringe.

Features

- Ideal to concentrate hydrophobic trace substances in water samples.

- High recovery rate in pesticides even in polar metal coordinating compounds such as Ashram and oxine copper.

- Rapid processing with vacuum concentrators and pressurized flow pump for collection and concentration.

- A combination of Wakopak® Wakosil® Agri-9 and special eluent enables a easy and quick HPLC analysis of various pesticides.

- GC analysis can be carried out in high selectivity using Trajan (SGE) capillary columns.

Analytical Example (LC-MS/MS)

-

Column:Presep®-C Agri (Short)

pre-conditioning for column

① CH3CN 10 mL

② CH3OH 10mL

③ H2O 10mL

1) flow sample water: 500 mL*1

2) washing: H2O 5 mL

3) extraction by CH3CN 2 mL

4) concentrate (to 0.2〜0.3 mL) under N2

5) dissolve into 1mL of H2O

6) analysis by HPLC (10 μL injection)*1 500 mL of sample: add 10 mL of 0.2 mol/L EDTA・2Na, pH3.5 by diluted HNO3 (conc.HNO3/H2O=1/10)

-

HPLC conditions

Column : Wakopak® MS-Agri-9 GT (2.0 mmφ x 150 mm) Eluent : A)10 mM CH3COONH4 (pH3.7)

B)CH3CN

0-10min.: B=12-70 %

10-13min.: B=100 %

13-23min.: B=12 %Flow Rate :0.2 mL/min. at 40 ℃ Injection Vol. :each 1 ppm、2 μL MS/MS conditions

ESI, MRM

Ion Spray Voltage: 5500V (pos) -4500V (neg) Temperature: 700 ℃ 300 ℃ Curtain Gas: 40 20 Collision Gas: 5 3 Ion Source Gas1: 80 40 Ion Source Gas2: 70 80 System: 3200Q TRAP(ABI) -

-

Results

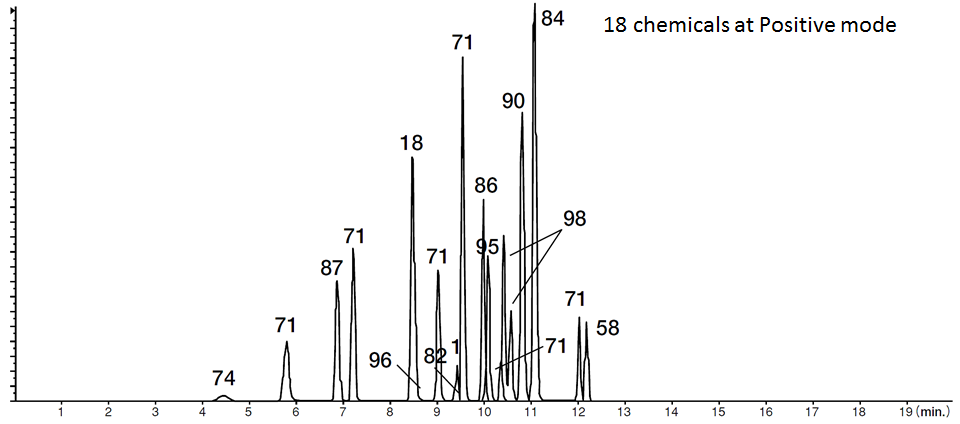

18 components at positive mode

| No.*1 | Chemical Name | Q1/Q3 | RT (min) | Recovery Rate (%) |

|---|---|---|---|---|

| 74 | Methomyl | 163.1/88.1 amu | 4.4 | 50.8 (85.2)*2 |

| 71 | MPP oxon sulfoxide | 279.0/104.2 amu | 5.8 | 101.6 |

| 87 | Tricyclazole | 190.0/163.2 amu | 6.9 | 99.1 |

| 71 | MPP oxon sulfone | 295.0/217.1 amu | 7.2 | 99.7 |

| 18 | Carbofuran (metabolite of Carbosulfan) | 222.1/165.2 amu | 8.5 | 103.1 |

| 96 | Thiodicarb | 355.1/88.1 amu | 8.6 | 99.6 |

| 71 | MPP sulfoxide | 294.9/109.0 amu | 9.0 | 100.1 |

| 1 | Thiuram | 240.9/88.1 amu | 9.5 | 94.3 |

| 82 | Probenazole | 224.0/130.2 amu | 9.5 | 98.6 |

| 71 | MPP oxon | 263.0/231.1 amu | 9.6 | 99.5 |

| 86 | Bensulfuron-methyl | 411.0/149.2 amu | 10.0 | 100.7 |

| 95 | Flazasulfuron | 408.2/182.1 amu | 10.1 | 98.6 |

| 71 | MPP sulfone | 310.9/124.9 amu | 10.4 | 99.2 |

| 98 | Siduron peak1 | 233.1/137.2 amu | 10.4 | 99.7 |

| 98 | Siduron peak2 | - | 10.6 | 98.3 |

| 90 | Azoxystrobin | 404.1/372.1 amu | 10.8 | 99.6 |

| 84 | Dymron | 269.1/151.1 amu | 11.1 | 99.6 |

| 71 | MPP | 279.0/169.0 amu | 12.1 | 104.3 |

| 58 | Carpropamid | 336.0/139.2 amu | 12.2 | 101.8 |

*1 same number as Japanese Waterworks Act, Appendix.

*2 figure in parentheses is recovery rate when Presep® Agri was employed.

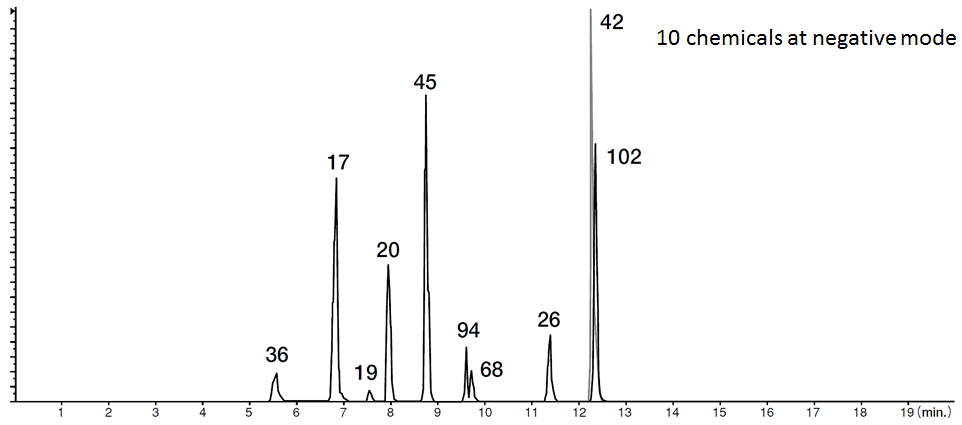

10 components at negative mode

| No.*1 | Chemical Name | Q1/Q3 | RT (min) | Recovery Rate (%) |

|---|---|---|---|---|

| 36 | Asulam | 228.9/196.7 amu | 5.7 | 99.6 |

| 17 | Bentazone | 239.1/131.6 amu | 6.8 | 99.3 |

| 19 | 2,4-PA | 219.9/161.7 amu | 7.5 | 99.1 |

| 20 | Triclopyr | 255.9/198.1 amu | 8.0 | 101.2 |

| 45 | MCPP(Mecoprop) | 213.0/140.9 amu | 8.8 | 99.9 |

| 94 | Halosulfuron-methyl | 433.6/252.2 amu | 9.6 | 99.1 |

| 68 | DCMU(Diuron) | 232.0/186.9 amu | 9.7 | 100.4 |

| 26 | Iprodione | 329.9/245.1 amu | 11.4 | 98.9 |

| 42 | Bensulide(SAP) | 395.9/212.7 amu | 12.3 | 96.7 |

| 102 | Fipronil | 436.8/330.1 amu | 12.4 | 97.3 |

*1 same number as Japanese Waterworks Act, Appendix.

Other 3 components without mixing*3

| No.*1 | Chemical Name | Recovery Rate (%) |

|---|---|---|

| 28 | Oxine-copper | 96.2 |

| 48 | Carbary (l NAC) | 101.0 |

| 75 | MBC (decomposition product of Benomyl) | 97.5 |

*1 same number as Japanese Waterworks Act, Appendix.

*3 due to stability in mixture solution.

Example by Presep®-C Agri (Short)

-

SPE Conditions

Column :Presep®-C Agri (Short) Pre-conditioning :dichloromethane (5 mL), methanol (5 mL), DI water (5 mL) Sample :add 100 µL of standard solution into DI 200 mL of water SPE treatment :flow=10-20 mL/min. Draining :air flow for 10 min. Extraction and dryness :Attach two of Presep®-C Na2SO4 at the outlet and charge 2.5 mL of dichloromethane to extract. Then, remove Presep®-C Agri (Short) and Charge 6 mL of dichloromethane into Na2SO4 column. Combine crude solution. Concentration :add 2 mL of hexane and concentrate crude solution under N2 to ca. 0.8 mL (don't completely dryness). analytical sample :add 100 μL of internal standard solution and add 1 mL of hexane (sample solution should be in freezer to keep concentration due to vapolize). Standard :10 μg/mL acetone solution Internal standard solution :2 μg/mL of hexane solution with acenaphthene and chrysene (for adjusting agent for sensitivity of GC/MS analysis) GC conditions

GC : HP5890 PACKARD SERIESE GC/MS GC/MS : AUTO mass JMS-AM150 (JEOL) Column : 100 % dimethylpolysiloxane, 0.25 mmφ x 30 m, thickness=0.25 μm Injector : 250 ℃ Temp. : 60℃ (2min)-120℃ (20℃/min)-300℃(10℃/min)-300℃(5min) injection : 2.0 μL -

No. Chemical name Recovery rate (%) 27 etridiazole 92.3 30 chloroneb 91.8 33 pencycuron 90.8 43 benfluralin 82.3 2 simazine 101.5 10 propyzamide 95.8 9 TPN 95.8 6 diazinon 97.7 38 MBPMC 106.3 31 tolclofos-methyl 89.7 34 metalaxyl 100.7 7 MEP 97.3 37 dithiopyr 89.4 23 chlorpyrifos 88.9 29 captan 103.9 44 pendimethalin 85.7 46 methyldymron 84.6 22 isofenphos 91.3 8 isoprothiolane 96.6 41 butamifos 84.1 32 flutolanil 100.3 39 napropamide 99.7 5 isoxathion 91.8 triclopyr-2-butoxyethyl 94.1 35 mepronil 116.6 40 pyributicarb 93.5 26 iprodione 98.0 25 pyridaphenthion 106.5 11 DDVP(Dichlorvos) 108.9 12 BPMC 107.5 3 Thiobencarb 101.0 15 IBP 115.1 13 CNP 112.0 16 EPN 115.4

Product List

- Open All

- Close All

SPE Column

HPLC Column

Solvent for Exclusive Use

For research use or further manufacturing use only. Not for use in diagnostic procedures.

Product content may differ from the actual image due to minor specification changes etc.

If the revision of product standards and packaging standards has been made, there is a case where the actual product specifications and images are different.