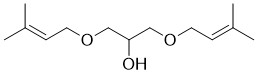

1,3-Bis[(3-methyl-2-buten-1-yl)oxy]-2-propanol

- for Organic Synthesis

- Specification Assay :

- 97.0+% (capillary GC)

- Manufacturer :

- FUJIFILM Wako Pure Chemical Corporation

- Storage Condition :

- Keep at RT.

- CAS RN® :

- 2337348-25-9

- Molecular Formula :

- C13H24O3

- Molecular Weight :

- 228.33

- GHS :

-

- Structural Formula

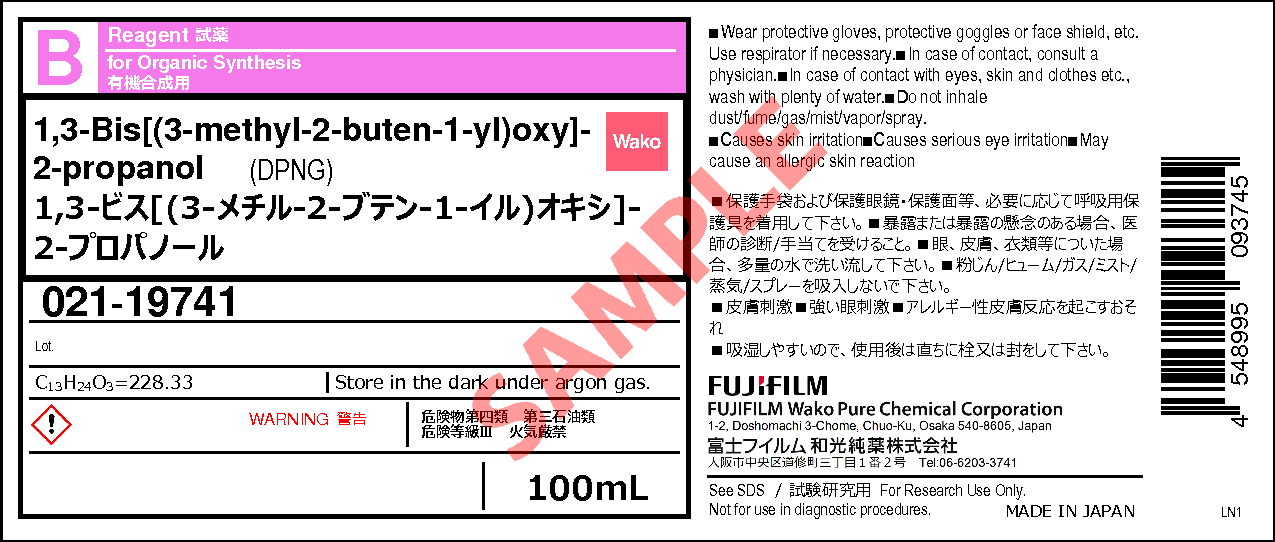

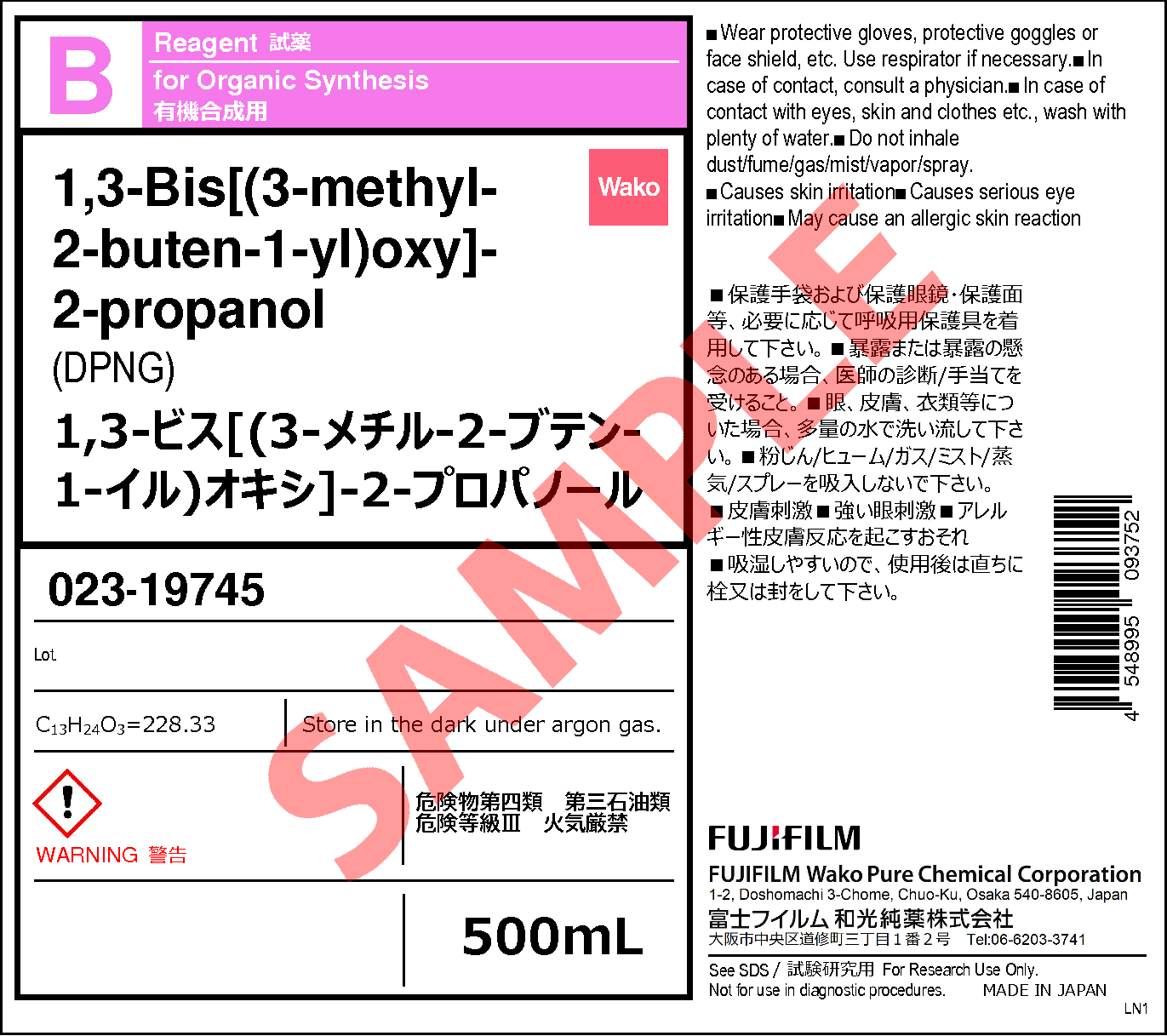

- Label

- Packing

- SDS

|

Comparison

|

Product Number

|

Package Size

|

Price

|

Availability

|

Certificate of Analysis

|

Purchase |

|---|---|---|---|---|---|---|

|

|

|

100mL

|

|

In stock in Japan |

||

|

|

|

500mL

|

|

In stock in Japan |

※Check availability in the US with the distributor.

Document

Product Summary

1,3-Bis[(3-methyl-2-buten-1-yl)oxy]-2-propanol (DPNG) is an additive that has the function of absorbing and decomposing oxygen by itself, reducing the inhibition of curing caused by oxygen and promoting UV curing. In addition, by blending DPNG into the resin, it is possible to suppress oxygen-triggered yellowing and degradation of the resin.

Physical Properties and Features

Physical properties

| Boiling point (℃) | Melting Point (℃) | Viscosity (25℃) (mPa・s) |

Refraction Index (d line, 25℃) |

|---|---|---|---|

| 292 | <-90 | 9.18 | 1.47 |

Features

- Absorbs and decomposes oxygen by itself.

- In UV curing under an air atmosphere, it suppresses reaction inhibition due to oxygen and accelerates curing.

- By adding it to the resin, it is possible to suppress the yellowing deterioration of the resin triggered by oxygen.

Applications

Oxygen absorption capacity of DPNG

The results of the oxygen absorption capacity of DPNG are shown in Figure 1. Compared with N-methyldiethanolamine (MDEA), which is a known oxygen absorbing material, DPNG showed superior oxygen-absorbing effect and did not use metal catalysts required for aryl glycidyl ether (AGE). DPNG can be used as an additive in a variety of applications because it does not have the coloration and odor observed with amine compounds.

Figure 1. Oxygen absorption capacity test of DPNG

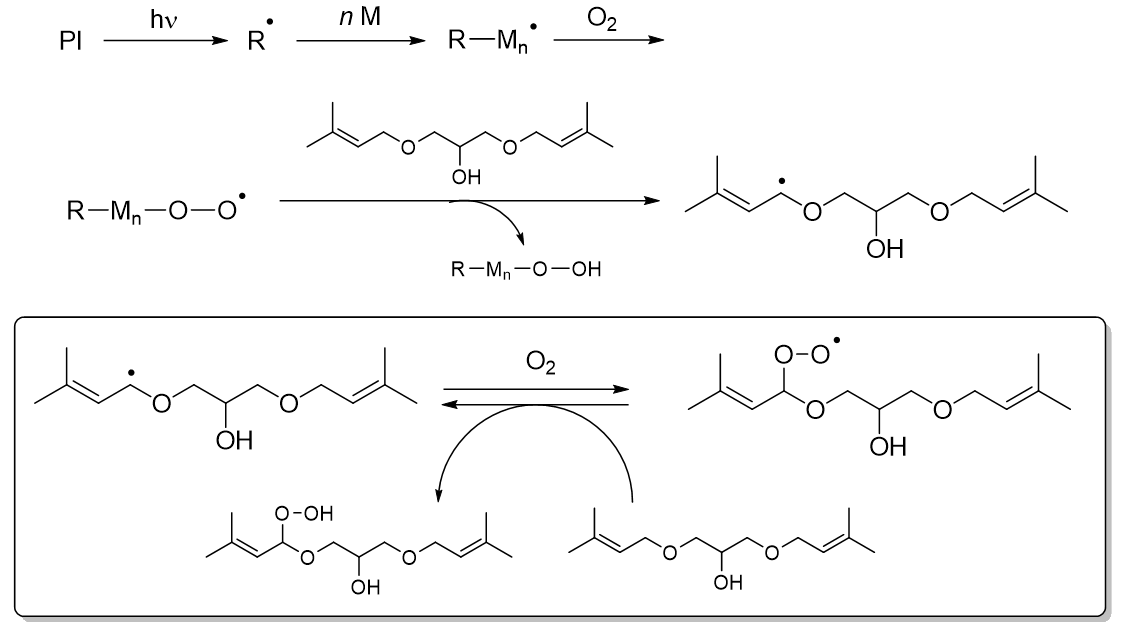

Figure 2 shows the oxygen absorption mechanism of DPNG estimated from decomposition analysis. During the reaction, a radical is generated at the allylic position of DPNG, which then reacts with oxygen to generate a peroxide radical of DPNG and oxygen is captured. The generated peroxide radicals are thought to regenerate DPNG radicals by abstracting hydrogen from other DPNG, and the oxygen absorption cycle of DPNG proceeds.

Figure 2. Presumed oxygen absorption mechanism of DPNG

Figure 2. Presumed oxygen absorption mechanism of DPNG

Accelerated UV curing

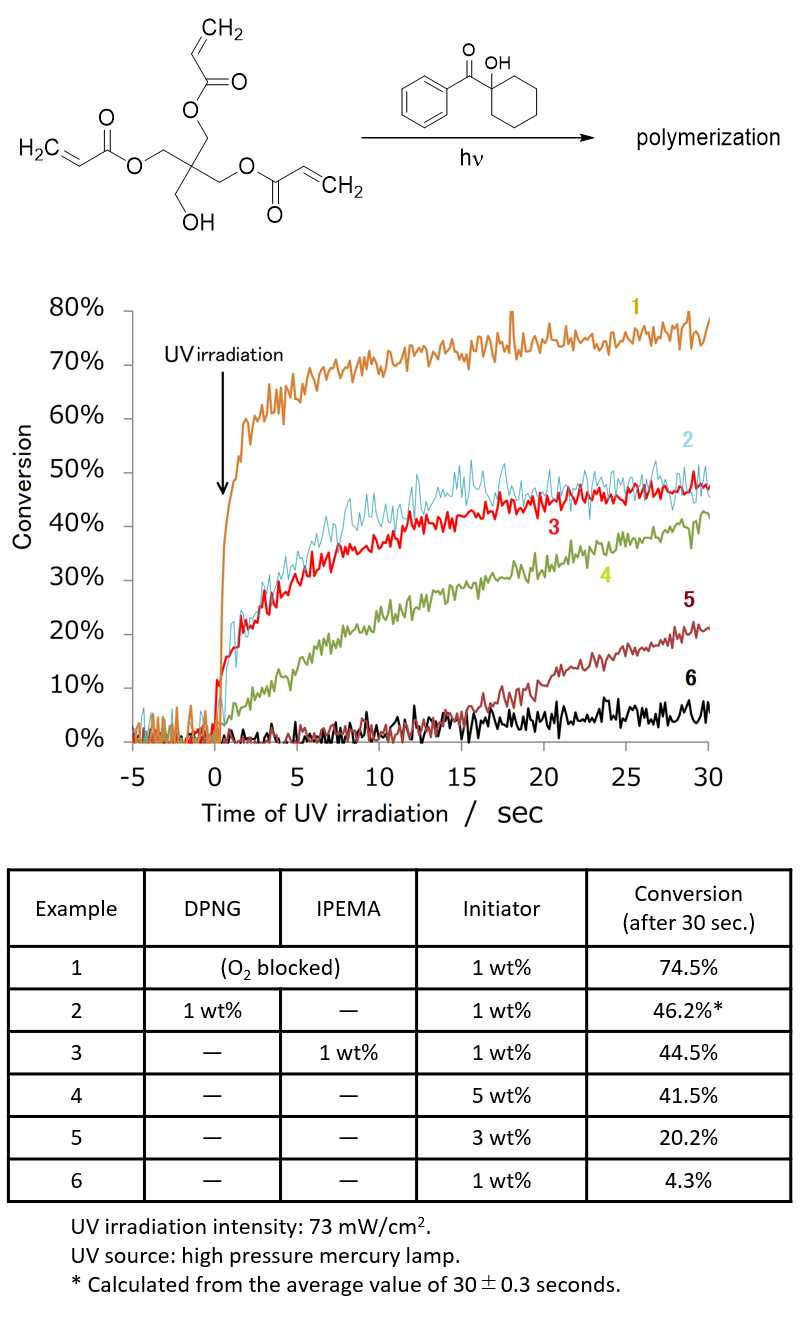

Figure 3 shows the time course of UV curing using DPNG as additives. Pentaerythritol triacrylate was used as a monomer and 1-hydroxycyclohexyl phenyl ketone was used as an initiator, and the change in the conversion of olefin was tracked using real-time IR measurements. While the curing proceeded with the conversion of 74.5% within 30 seconds under oxygen-blocked conditions (example 1), the conversion in the air remained at 4.3% due to the influence of oxygen (example 6). On the other hand, when DPNG was added, the conversion was 46.2%, even in the air, and the conversion improved by more than 10 times (example 2). In addition, looking at the change in the conversion over time, it is also a significant feature that the addition of DPNG causes the reaction rate to rise sharply immediately after UV irradiation, as in the case of the oxygen-blocking condition.

Figure 3. Change over time of olefin conversion by UV irradiation

Figure 3. Change over time of olefin conversion by UV irradiation

Suppression of resin yellowing

Resin components contained in paints and coatings are subject to oxidation over time, and this oxidation causes resin deterioration such as yellowing and cracking. Therefore, antioxidants are added to many paints and coatings. But particularly, phenolic antioxidants can act as a stopping agent for radical polymerization and can cause curing defects, making it difficult in some cases to add a sufficient prescription amount to prevent oxidation.

DPNG has oxygen absorption properties, so it functions as an additive to prevent oxidative deterioration of resins, which is triggered by oxygen. While most common antioxidants are solids, DPNG is a liquid and exhibits high compatibility with resins and coating solution. When DPNG is formulated into a UV-curable composition, DPNG acts as a curing accelerator during UV curing and as an antioxidant to prevent resin deterioration after curing.

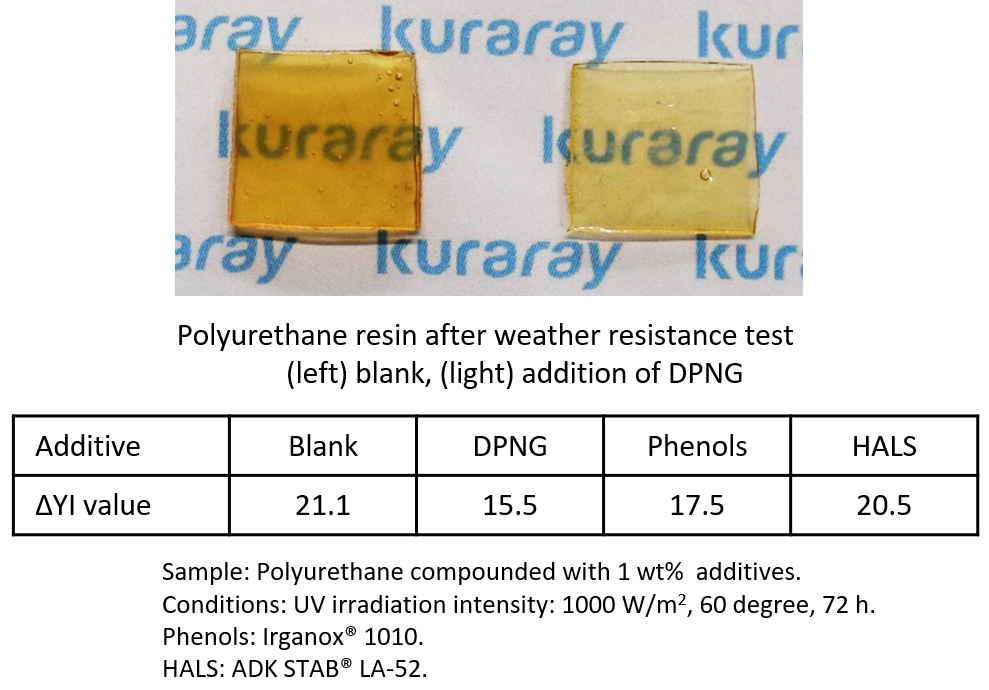

Figure 4 shows the weather resistance test of a polyurethane resin containing DPNG. The DPNG-added product has a smaller ΔYI value (a value that indicates the amount of change in the degree of yellowing) compared to non-added products and other antioxidants, indicating that yellowing is suppressed. While existing antioxidants prevent oxidation by quenching radical species and peroxides, DPNG prevents oxidation by absorbing and decomposing oxygen itself. Therefore, a synergistic effect of antioxidant is expected by using DPNG together with existing antioxidants.

Figure 4. Effects of additives in weather resistance test of polyurethane resins

Figure 4. Effects of additives in weather resistance test of polyurethane resins

* DPNG is developed by Kuraray Co., Ltd..

Overview / Applications

Property

| Appearance | Colorless - nearly colorless, clear liquid |

|---|

Manufacturer Information

Alias

- Diprenyl Glycerin Ether

DPNG

1,3-Bis(3-methyl-2-butenoxy)-2-hydroxypropane

For research use or further manufacturing use only. Not for use in diagnostic procedures.

Product content may differ from the actual image due to minor specification changes etc.

If the revision of product standards and packaging standards has been made, there is a case where the actual product specifications and images are different.