Wetting Tension Test Mixture No.42.0

- for Determination of Wetting Tension

- Manufacturer :

- FUJIFILM Wako Pure Chemical Corporation

- Storage Condition :

- Protect from light.

- GHS :

-

- Structural Formula

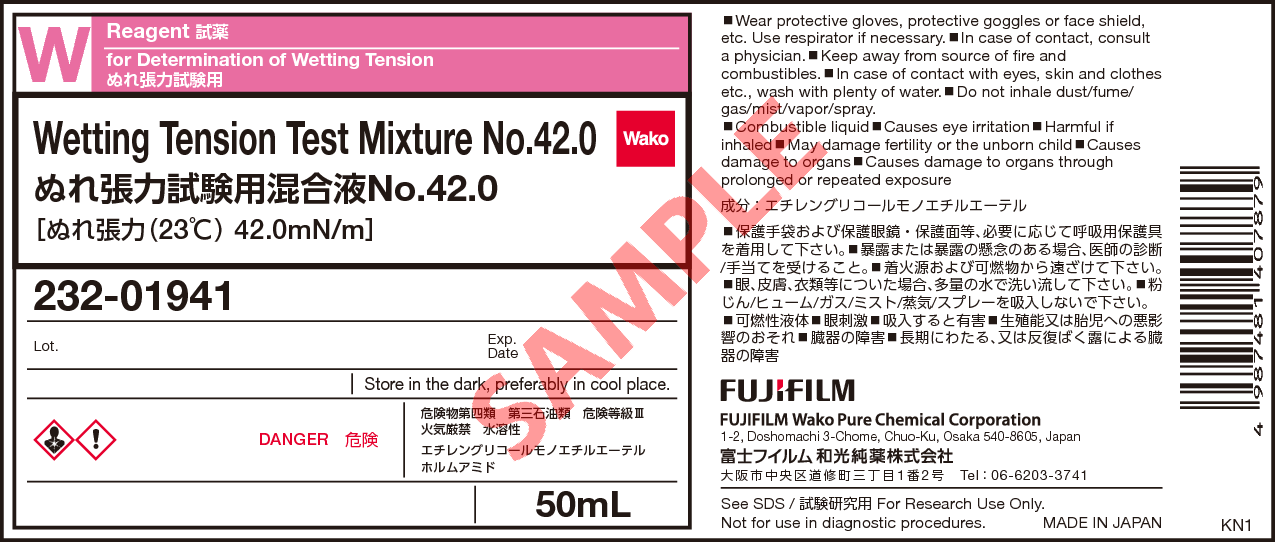

- Label

- Packing

- SDS

|

Comparison

|

Product Number

|

Package Size

|

Price

|

Availability

|

Certificate of Analysis

|

Purchase |

|---|---|---|---|---|---|---|

|

|

|

50mL

|

|

In stock in Japan |

※Check availability in the US with the distributor.

Document

Application

Overview / Applications

| Outline | Surface tension (23 degrees C) : 41.9 - 42.5mN/m This product is for research use only. Do not administer it to human. Wettability means a phenomenon of liquid spreading through the film surface. The index showing the degree of wetness is referred to as tensile force. For application of paint or coating on a plastic film or adhesion of a plastic film, it is necessary for plastic films to retain ink, coating agent and adhesives. Wet tensile force is used as a measure for expressing this retention capacity.The testing method of wetting tension had been specified in JIS K6768. However, in order to coordinate with the ISO International Standard, it has been drastically revised based on ISO 8296. By this revision, the types of liquid mixture for testing have increased, and the application range expanded from polyethylene and polypropylene to plastic film and sheets in general.To the popular conventional wet index standard solutions, we have added 16 new types available in wetting tension test from 22.6 to 30.0 and from 56.0 to 73.0 according to JIS K6768 revision. All products have been renewed and we have started sales of 36 types as liquid mixtures for wetting tension test.(Note) The color tones will differ slightly from the conventional products due to the colorants used for more stable quality. It is harmless for use. |

|---|

Property

| Appearance | Blue liquid |

|---|

Manufacturer Information

Alias

For research use or further manufacturing use only. Not for use in diagnostic procedures.

Product content may differ from the actual image due to minor specification changes etc.

If the revision of product standards and packaging standards has been made, there is a case where the actual product specifications and images are different.