Quality Inspection of Wakopak® Silica Gel Packing Agents

FUJIFILM Wako inspects the Wakopak® silica gel packing agent for each lot. We inspect physical properties, such as particle shape and particle size, fill the column, and perform quality inspection using various types of samples per inspection.

FUJIFILM Wako provides selected packing agents that pass through rigorous conditions, offering you peace of mind for various analyses.

Contents of Quality Inspection

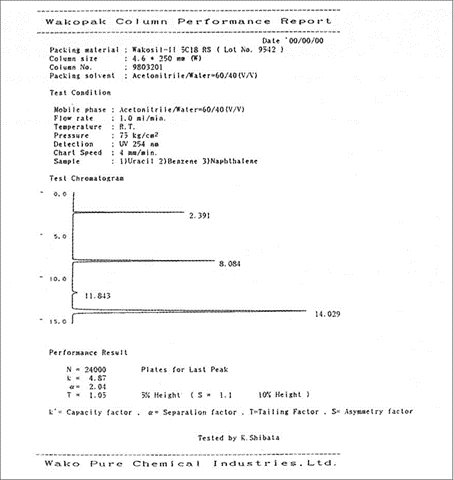

Wakopak® Column Performance Report

We inspect the packing conditions of each column for quality assurance.

- Number of theoretical plates (Naphthalene)

- Retention factor (Naphthalene)

- Separation factor (Naphthalene / Benzene)

- Peak symmetry (Naphthalene), tailing factor and symmetry factor (10% peak height)

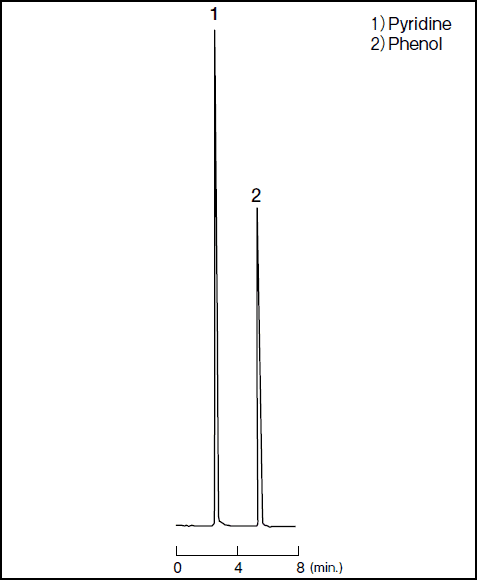

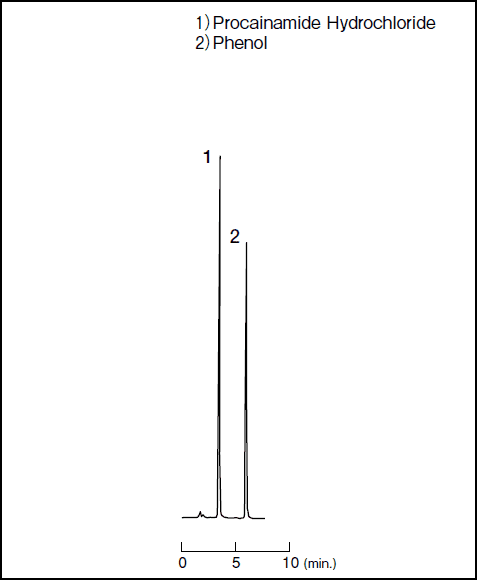

Examples of an Endcapping Test Method (Basic Compounds)

Basic compounds are known to induce adsorption and tailing due to the influence of residual silanol of the packing agent. We use Pyridine and Procainamide, a basic compound, to test the endcapping efficiency of packing agent.

-

-

Column

Eluent

Flow Rate

Press

Detection:Wakopak® Wakosil®-Ⅱ5C18 RS (4.6 mm x 150 mm)

:CH3CN/H2O=30/70 (v/v)

:1.0 mL/min. at 35℃

:50 kg/cm2

:UV 254 nm

-

-

Column

Eluent

Flow Rate

Detection:Wakopak® Wakosil®-Ⅱ5C18 RS (4.6 mm x 150 mm)

:CH3OH/20mM K2HPO4 (pH7.6) =40/60 (v/v)

:1.0 mL/min. at 30℃

:UV 254 nm

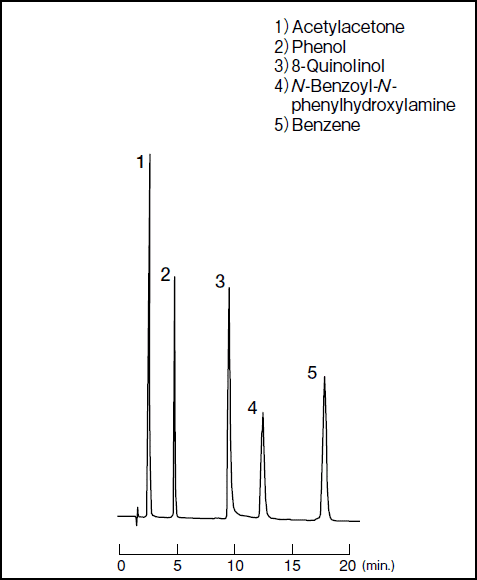

Example of Test Method for Metal Coordination Compounds

Metal coordination compounds are known to induce adsorption and tailing due to the influence of metal on the surface of the packing agent. The influence of contained metals is examined using a metal coordination compound, such as Hinokitiol.

-

-

Column

Eluent

Flow Rate

Detection:Wakopak® Wakosil®-Ⅱ5C18 HG (4.6 mm x 150 mm)

:CH3CN/20mM K2HPO4 (pH7.6) =40/60 (v/v)

:1.0 mL/min. at 30℃

:UV 254 nm 0.16 AUFS

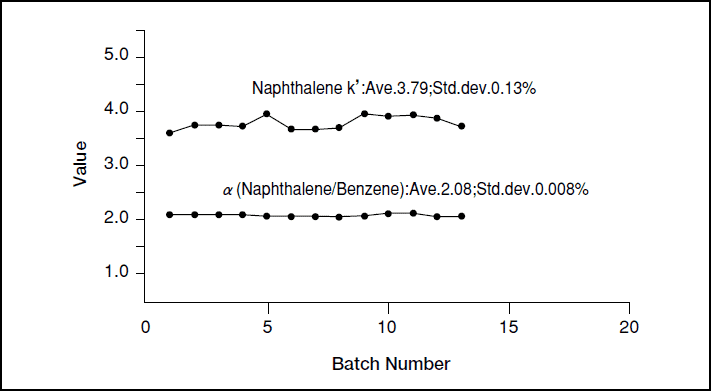

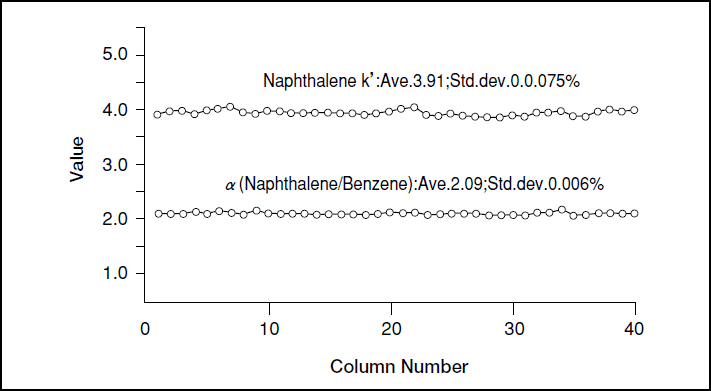

Examples of a Test Method for Interlot Validation (Retention Factor / Separation Factor)

The column packing status is controlled by examination of Uracil, Benzene, and Naphthalene. We supply a stable column with a smaller interlot difference in the packing agent and columns.

-

-

Column

Eluent

Flow Rate

Sample:Wakopak® Wakosil®-Ⅱ 5C18 HG (4.6 mm x 150 mm)

:CH3CN/H2O=60/40 (v/v)

:1.0 mL/min.

:Uracil, Benzene, Naphthalene

-

-

Column

Eluent

Flow Rate

Sample:Wakopak® Wakosil-Ⅱ® 5C18 HG (4.6 mm x 150 mm)

:CH3CN/H2O=60/40 (v/v)

:1.0 mL/min.

:Uracil, Benzene, Naphthalene

For research use or further manufacturing use only. Not for use in diagnostic procedures.

Product content may differ from the actual image due to minor specification changes etc.

If the revision of product standards and packaging standards has been made, there is a case where the actual product specifications and images are different.