(Copy) Wakopak® Wakosil®-II Prep Series (C18, SIL) (for Preparative Chromatography)

Wakopak® Wakosil®-II Prep series is a preparative column series using high-purity silica gel packing agents with low metal content, ideal for the preparative analysis of analytes that are affected by metal impurities.

For reverse phase chromatography HPLC columns, the same lineup as the Wakopak® Wakosil®-II HG, AR, and RS series with analytical validation support is available as the Wakopak® Wakosil®-II 5C18 Prep series.

For normal phase chromatography HPLC columns, the same lineup as the Wakopak® Wakosil® SIL series using high-purity silica gel is available as the Wakopak® Wakosil®-II 5SIL Prep.

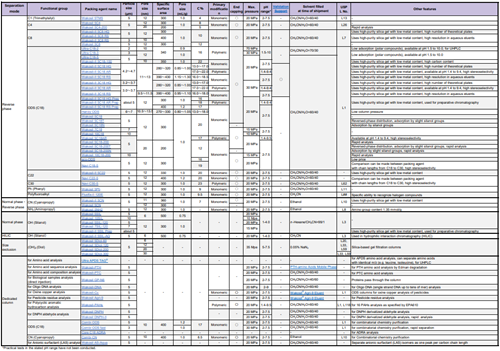

Wakopak® Series Information (Packing Agents, Particle Size, Column Pressure, pH Range, etc.)

Wakopak® Wakosil®-II Prep Series Overview

Wakopak® Wakosil®-II Prep Series Features

- High purity silica gel with low metal content is used.

- Unique features of the series (AR, HG, RS) are available.

- Packing agents with the same separation characteristics are available from analysis to preparative size (packed with the same packing agent).

| Wakosil®-II HG Prep*1 | Wakosil®-II RS Prep*2 | Wakosil®-II AR Prep*3 | Wakosil®-II 5SIL Prep | |

|---|---|---|---|---|

| Features | High theoretical number of plates | High resolution in aqueous eluents | High stereoselectivity and column durability | Standard normal phase columns |

| Applications | First choice for Wakosil®-II series | Preparation of compounds with a high range of polarity |

|

|

| Chemical modification |

C18 | C18 | C18 | OH (unmodified) |

| Particle size | about 5 μm | about 5 μm | about 5 μm | about 5 μm |

| Primary modification |

monomeric | monomeric | polymeric | - |

| Column I.D.*4 | 4.6 mm, 10 mm, 20 mm, 50 mm | 4.6 mm, 10 mm, 20 mm, 50 mm | 4.6 mm, 10 mm, 20 mm, 50 mm | 4.6 mm, 20 mm, 50 mm |

*1 Wakosil®-II HG Prep: The highest number of theoretical plates among our column products.

*2 Wakosil®-II RS Prep: High retention capacity due to its large specific surface area. Because of its thorough end capping treatment, it has high separation and retention capacity even with aqueous eluents, making it suitable for the separation of highly polar compounds.

*3 Wakosil®-II AR Prep: This product has excellent stereoselectivity due to its polymeric type chemical modification. Also, the mobile phase can be used over a wide pH range due to its extremely high durability.

*4 Prep series columns are available in 4.6, 10, 20, and 50 mm I.D. columns. For sizes not listed in the product list, please contact us.

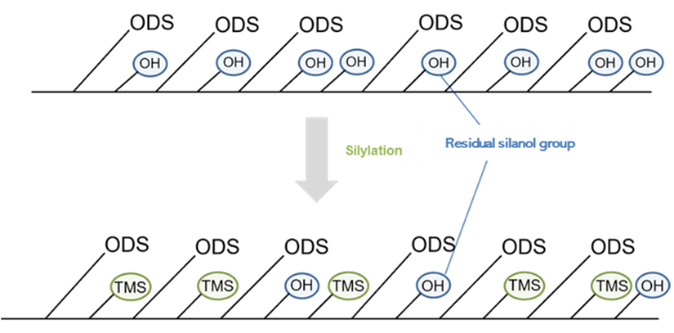

End Capping

The reaction between the silanol groups of silica gel and silylating agent is affected by steric hindrance and other factors, so some silanol groups may remain. These residual silanol groups can cause peak tailing of basic compounds and affect separation. Further silylation to remove the residual silanol groups is called end capping. Silane compounds such as trimethylchlorosilane (TMS) are mainly used for end capping.

[Example of end capping on an ODS column]

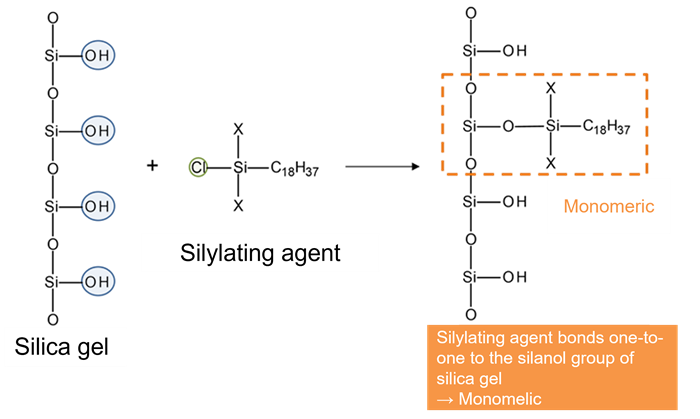

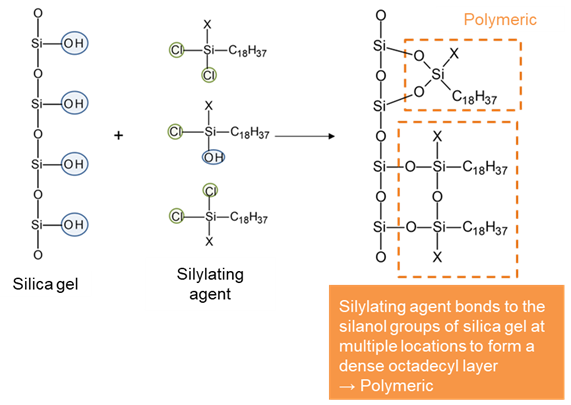

Monomeric and Polymeric

Monomeric refers to a structure in which the silylating agent and the silanol group on the silica gel are bonded one-to-one. Polymeric refers to a structure in which multifunctional silylating agents polymerize with each other or one silylating agent bonds to silica gel at multiple silanol groups during the ODS modification of silica gel, forming a dense octadecyl layer.

[Monomeric]

[Polymeric]

Preparative Condition Setting

Consideration of optimum separation conditions in a preparative column requires a large number of samples, and the preparative columns are expensive. Therefore, the usual approach is to set the conditions in advance on an analytical size column and transfer them to a preparative size column.

Fujifilm Wako offers columns packed with the same packing agent from analytical to preparative size, which enables smooth transfer of preparative conditions.

For example, the following is an example of preparation of Arbutin using Wakopak® Wakosil®-II 5C18RS Prep. The Wakopak® Wakosil®-II Prep series uses a packing agent with a large particle size (about 5 μm), which allows the column pressure to be kept low even when the flow rate is increased. The columns are available in 4.6 mm to 50 mm I.D., depending on the preparative scale.

Preparative Condition Setting Procedure

- 1. Determine the preparative conditions with an analytical size column (4.6 mm × 250 mm).

- →Select an appropriate packing agent, mobile phase, and other separation conditions on an analytical scale.

- 2. Set the sample loading volume (injection volume) and flow rate based on the ratio of column cross sectional area between analytical size column and preparative column.

- →If the same packing agent can be used for both analytical and preparative columns, equivalent separation can be obtained at approximately the same column pressure by setting the flow rate and the injection volume in proportion to the cross-sectional area of the column.

- 3. Perform preparation with a preparative column.

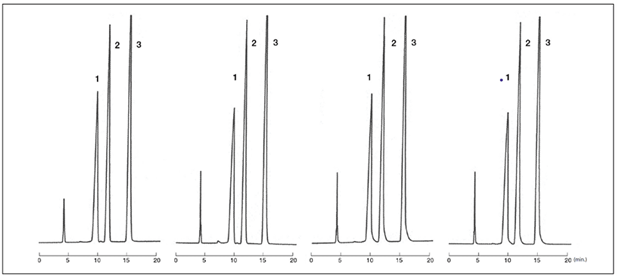

Analysis Example of Arubutin (Preparative Example)

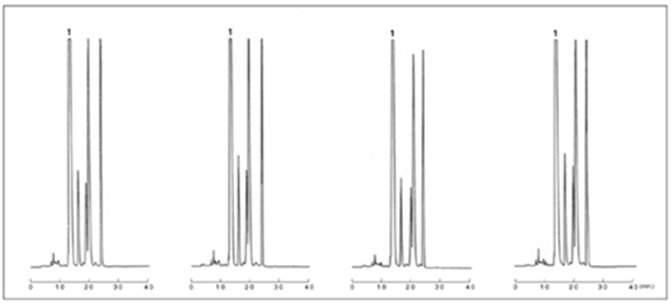

Suppose that Arbutin analyzed on a 4.6 mm I.D. Wakopak® Wakosil®-II 5C18RS column is scaled up to 20 mm, 33 mm, and 50 mm I.D. columns with the same packing agent, particle size, and column length. It is assumed that almost equivalent chromatograms can be obtained by increasing the flow rate and the injection volume* to match the cross-sectional area ratio. The following chromatograms actually measured show that the peak shape, peak width, and retention time of each component are almost equivalent.

Thus, if a pair of columns with the same packing agent and different I.D. are available, scale-up can be easily performed.

* There are two ways to set the sample loading volume: concentration loading, in which the injection volume is fixed and the sample concentration is increased, and volume loading, in which the sample concentration is fixed and the injection volume is increased. The volume loading method is used in this test.

| Peak No. | Component |

|---|---|

| 1 | Arbutin |

Analysis (Preparative) Conditions

|

||||||||

|

||||||||

|

||||||||

|

||||||||

|

* Cross sectional area ratio when the cross sectional area of a column with an I.D. of 4.6 mm is set to 1.

Cross sectional area = radius × radius × 3.14 (π).

Wakopak® Wakosil®-II HG Prep

It has the highest number of theoretical plates among our column products.

Click here for information on the analytical columns of the same series (Wakopak® Wakosil®-II HG).

Column Information

| Silica gel | High purity silica gel with low metal content |

|---|---|

| Average particle size | about 5 μm |

| Specific surface area | 300 m2/g |

| Pore size | 12 nm |

| Pore volume | 1.00 mL/g |

| Functional group | Octadecyl group (ODS, C18) |

| Primary modification | Monomeric |

| End cap processing | ✓ |

| Carbon content | 16.0% |

| USP Code | L1 |

| Column I.D. | 4.6 mm, 10 mm, 20 mm, 50 mm |

| Recommended pH range for use | 2-7.5 |

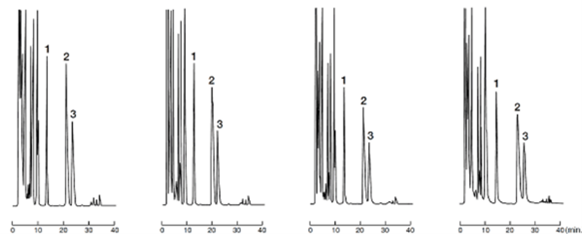

Toad Venom analysis (preparative)

| Peak No. | Component | Peak No. | Component | Peak No. | Component |

|---|---|---|---|---|---|

| 1 | Bufalin | 2 | Cinobufagin | 3 | Resibufogenin |

Analysis condition

| Column size | : | 4.6 mm × 250 mm | 20 mm × 250 mm | 33 mm × 50 mm | 50 mm × 250 mm | ||||||

| Flow Rate | : | 1.0 mL/min. | 18.9 mL/min. | 51.5 mL/min. | 115.8 mL/min. | ||||||

| Column pressure | : | 60 kg/cm2 | 54 kg/cm2 | 58 kg/cm2 | 60 kg/cm2 | ||||||

| Injection volume | : | 20 μL | 380 μL | 1.0 mL | 2.3 mL | ||||||

| Column | : | Wakopak® Wakosil®-II 5C18HG Prep | |||||||||

| Colum temperature | : | R.T. | |||||||||

| Eluent | : | A) CH3CN/0.1%CH3COOH=40/60 (v/v) B) CH3CN/0.1%CH3COOH=80/20 (v/v) |

|||||||||

| Gradient | : |

|

|||||||||

| Detection | : | UV 300 nm | |||||||||

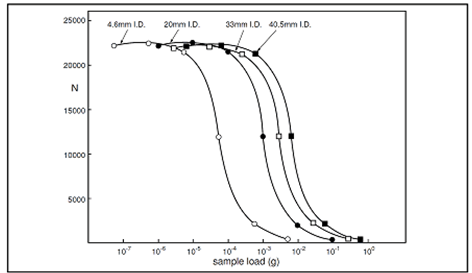

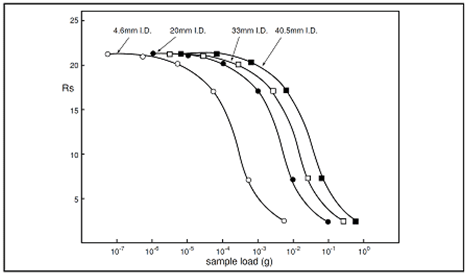

for Prep series and analytical columns

for Prep series and analytical columns

| Sample | : | N) Dibutyl phthalate Rs) Dipropyl phthalate, Dibutyl phthalate |

| Column | : | Wakopak® Wakosil®-II 5C18HG Prep |

| Column size | : | 4.6 mm × 250 mm, 20 mm × 250 mm, 33 mm × 250 mm, 50 mm × 250 mm |

| Eluent | : | CH3CN/H2O=65/35 (v/v) |

Wakopak® Wakosil®-II RS Prep

Wakopak® Wakosil®- II RS Prep is thoroughly end capped and can be used with aqueous eluents. Therefore, mixed samples with a wide range of polarities and basic compounds can be separated without tailing.

In addition, it has a large specific surface area of 400 m2/g and shows high retention capacity.

Click here for information on the analytical columns of the same series (Wakopak® Wakosil®-II RS).

Column Information

| Silica gel | High purity silica gel with low metal content |

|---|---|

| Average particle size | about 5 μm |

| Specific surface area | 400 m2/g |

| Pore size | 12 nm |

| Pore volume | 1.20 mL/g |

| Functional group | Octadecyl group (ODS, C18) |

| Primary modification | Monomeric |

| End cap processing | ✓ |

| Carbon content | 17.0% |

| USP Code | L1 |

| Column I.D. | 4.6 mm, 10 mm, 20 mm, 50 mm |

| Recommended pH range for use | 2-7.5 |

Arbutin analysis (preparative)

| Peak No. | Component |

|---|---|

| 1 | Arbutin |

Analysis condition

| Column size | : | 4.6 mm × 250 mm | 20 mm × 250 mm | 33 mm × 250 mm | 50 mm × 250 mm | ||||||||

| Flow Rate | : | 0.8 mL/min. | 15.1 mL/min. | 41.2 mL/min. | 92.6 mL/min. | ||||||||

| Column pressure | : | 45 kg/cm2 | 46 kg/cm2 | 49 kg/cm2 | 44 kg/cm2 | ||||||||

| Injection volume | : | 20 μL | 380 μL | 1.0 mL | 2.3 mL | ||||||||

| Column | : | Wakopak® Wakosil®-II 5C18RS Prep | |||||||||||

| Colum temperature | : | R.T. | |||||||||||

| Eluent | : | A) CH3COOH/H2O=1/99 (v/v) B) CH3CN/H2O=30/70 (v/v) |

|||||||||||

| Gradient | : |

|

|||||||||||

| Detection | : | UV 280 nm | |||||||||||

Wakopak® Wakosil®-II AR Prep

This column uses a polymeric type ODS packing agent and shows very high durability as the ODS is not easily hydrolyzed even when the mobile phase is acidic (pH 1.4). Due to the bonding properties of polymeric ODS, separation behavior may differ from that of common monomeric ODS silica gel and may exhibit very specific behavior. Therefore, it is useful for the separation of peptides and structural isomers.

Click here for information on the analytical columns of the same series (Wakopak® Wakosil®-II AR).

Column Information

| Silica gel | High purity silica gel with low metal content |

|---|---|

| Average particle size | about 5 μm |

| Specific surface area | 300 m2/g |

| Pore size | 12 nm |

| Pore volume | 1.00 mL/g |

| Functional group | Octadecyl group (ODS, C18) |

| Primary modification | Polymeric |

| End cap processing | ✓ |

| Carbon content | 18.0% |

| USP Code | L1 |

| Column I.D. | 4.6 mm, 10 mm, 20 mm, 50 mm |

| Recommended pH range for use | 1.4-9.4 |

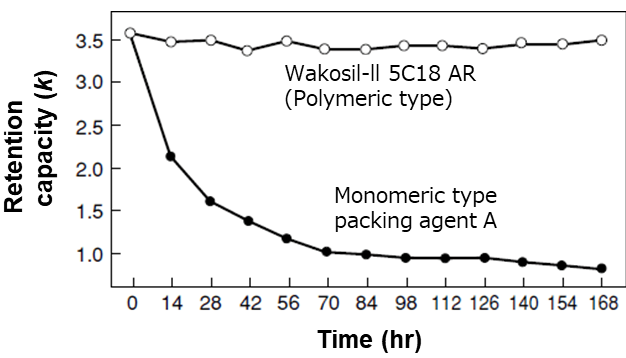

Acid Resistance Data*

High retention capacity at pH 1.4

Analysis condition

| Column | : | Wakopak® Wakosil®-II 5C18 AR 4.6 mm x 150 mm |

| Colum temperature | : | R.T. |

| Eluent | : | CH3CN/H2O=40/60 (v/v) |

| Flow rate | : | 1.0 mL/min. |

| Detection | : | UV 254 nm |

Procedure

After replacing each column with 1.0% trifluoroacetic acid solution (pH 1.4), the columns were placed in a thermostatic bath at 60°C and allowed to stand. Determine the retention capacity k (as the uracil peak at t0) of the naphthalene peak every 14 hours.

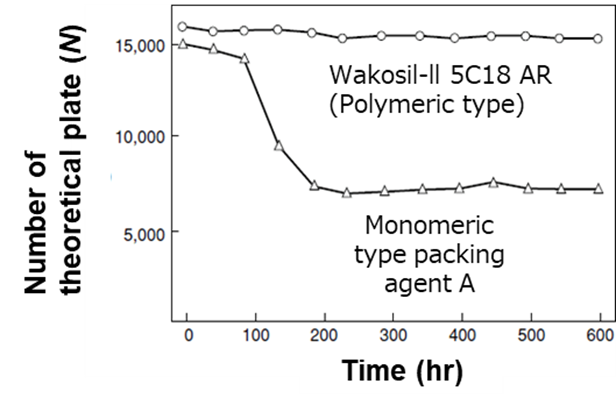

Base Resistance Data*

High number of theoretical plate at pH 9.4

Analysis condition

| Column | : | Wakopak® Wakosil®-II 5C18 AR 4.6 mm x 150 mm |

| Colum temperature | : | 40℃ |

| Eluent | : | 40% CH3CN in 20 mM Na2HPO4 (pH 9.4) |

| Flow rate | : | 1.0 mL/min. |

| Detection | : | UV 254 nm |

Procedure

Eluent was continuously pumped at 40°C to each packed column.

Determine the number of theoretical plates (N) from the N,N-dimethylaniline peak at the specified time.

* The above acid and base resistance data were measured using Wakopak® Wakosil®-II AR, not using preparative columns.

Wakopak® Wakosil®-II 5SIL Prep

Standard normal phase preparative column packed with silica gel without functional group modification. In this column, high purity silica gel with low metal content is used as packing agent, making it ideal for the preparative separation of compounds that are affected by metal impurities.

Click here for information on the analytical columns of the same series (Wakopak® Wakosil® SIL series).

Column Information

| Silica gel | High purity silica gel with low metal content |

|---|---|

| Average particle size | about 5 μm |

| Specific surface area | 300 m2/g |

| Pore size | 12 nm |

| Pore volume | 1.00 mL/g |

| Functional group | Silanol group (OH) |

| Primary modification | - |

| End cap processing | - |

| Carbon content | - |

| USP Code | L3 |

| Column I.D. | 4.6 mm, 20 mm, 50 mm |

| Recommended pH range for use | 1.0-4.0 |

Benzoate esters analysis (preparative)

| Peak No. | Component | Peak No. | Component | Peak No. | Component |

|---|---|---|---|---|---|

| 1 | Hexyl Benzoate | 2 | Propyl Benzoate | 3 | Methyl Benzoate |

Analysis condition

| Column size | : | 4.6 mm × 250 mm | 20 mm × 250 mm | 33 mm × 250 mm | 50 mm × 250 mm |

| Flow Rate | : | 1.0 mL/min. | 18.9 mL/min. | 51.5 mL/min. | 115.8 mL/min. |

| Column pressure | : | 18 kg/cm2 | 18 kg/cm2 | 16 kg/cm2 | 14 kg/cm2 |

| Injection volume | : | 10 μL | 190 μL | 500 μL | 1.15 mL |

| Column | : | Wakopak® Wakosil®-II 5SIL Prep | |||

| Colum temperature | : | R.T. | |||

| Eluent | : | n-Hexane/Ethyl Acetate=100/0.5 (v/v) | |||

| Detection | : | UV 254 nm | |||

Product List

- Open All

- Close All

Wakopak® Wakosil®-II 5C18 HG Prep

Wakopak® Wakosil®-II 5C18 AR Prep

Wakopak® Wakosil®-II 5C18 RS Prep

Wakopak® Wakosil®-II 5SIL Prep

For research use or further manufacturing use only. Not for use in diagnostic procedures.

Product content may differ from the actual image due to minor specification changes etc.

If the revision of product standards and packaging standards has been made, there is a case where the actual product specifications and images are different.

The prices are list prices in Japan.Please contact your local distributor for your retail price in your region.