WakogelR C-300E (45 - 75um, 75% up)

- for Column Chromatography

- Manufacturer :

- FUJIFILM Wako Pure Chemical Corporation

- Storage Condition :

- Keep at RT.

- CAS RN® :

- 63231-67-4

- Molecular Weight :

- 60.08

- Structural Formula

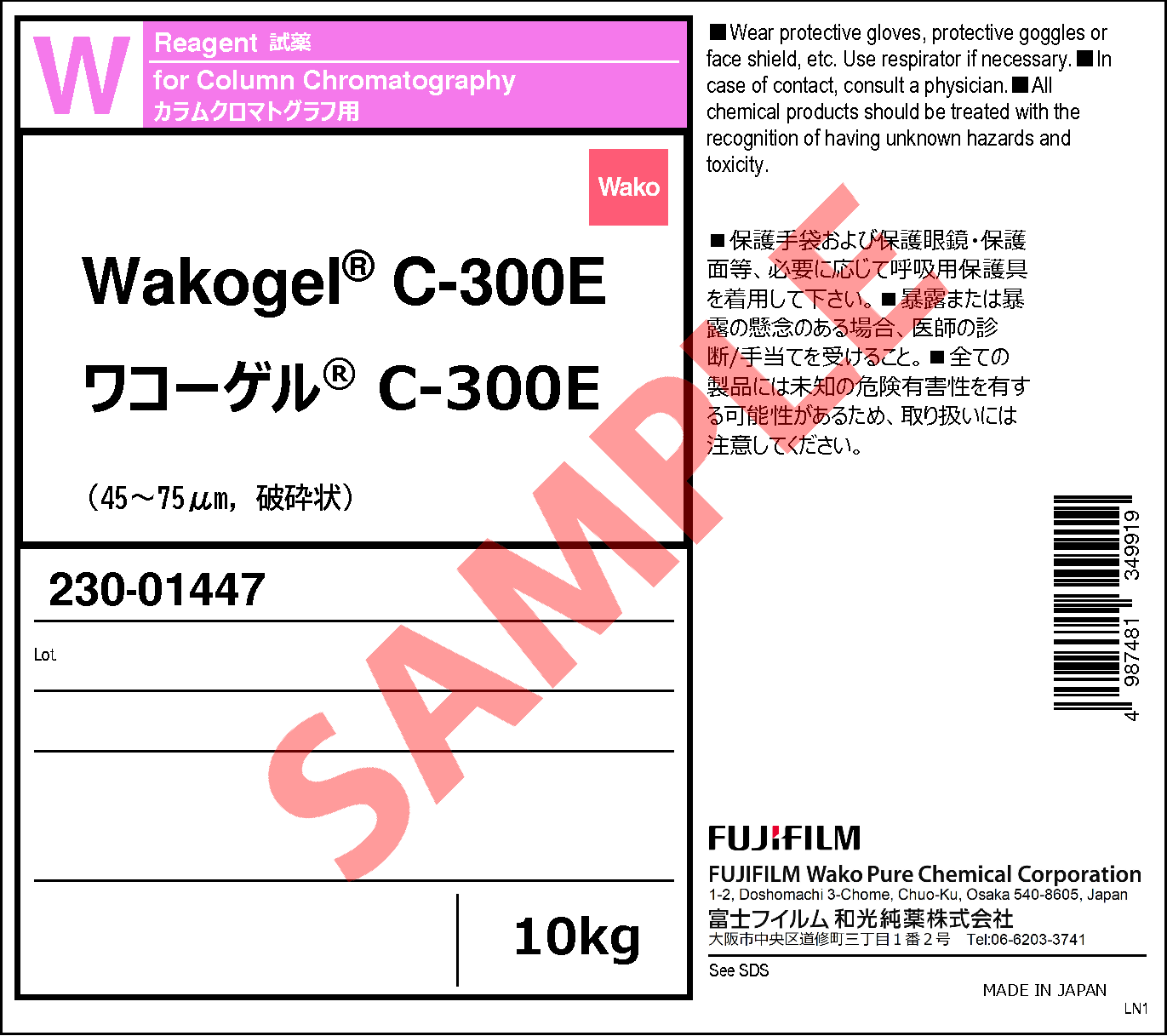

- Label

- Packing

|

Comparison

|

Product Number

|

Package Size

|

Price

|

Inventory

|

|

|---|---|---|---|---|---|

|

|

|

10kg

|

|

In stock in Japan |

Document

Application

Overview / Applications

| Outline | <Product for Column Chromatography><Adsorption Chromatography><Column Chromatography Packing Material><Adsorption/Reverse Phase Chromatography Packing Material>Silica gelIt is the most typical support with high physical strength, and is widely used as a filler for column chromatography. Silica gel itself is mostly used in adsorption chromatography for neutral and acidic samples.ODS filler that contains chemically-bound silica gel and hydrophobic silylation agents, etc. has also been used widely in the field of column chromatography in recent years due to its extensive applications for reverse phase chromatography.Wakogel C Series/C Series E TypeThe Wakogel C Series is total porous fractured silica gel that has been adjusted mainly for mass preparative isolation and purification. The adsorbed amount is higher than that of other silica gels, and therefore the loading amount of samples can be set higher. The product has the same property values as Wakogel LP Series, Wakogel FC Series, Silica Gel 70 for TLC, and Wakogel B Series. Utilizing the difference of the particle sizes, it is easy to change the method to another chromatography method.Wakogel C Series E Type is a type of C series but has not been acid-treated, and is best suited for large-scale rough purification. Its physical properties are similar to the C Series. |

|---|

Property

| Appearance | White powder |

|---|---|

| pH | pH (50g/l aqueous slurry,25 degrees C) :5.5 - 7.5 |

| Boiling Point | about 3,000 degrees C |

| Flash Point | None |

Manufacturer Information

Alias

For research use or further manufacturing use only. Not for use in diagnostic procedures.

Product content may differ from the actual image due to minor specification changes etc.

If the revision of product standards and packaging standards has been made, there is a case where the actual product specifications and images are different.